Notizie

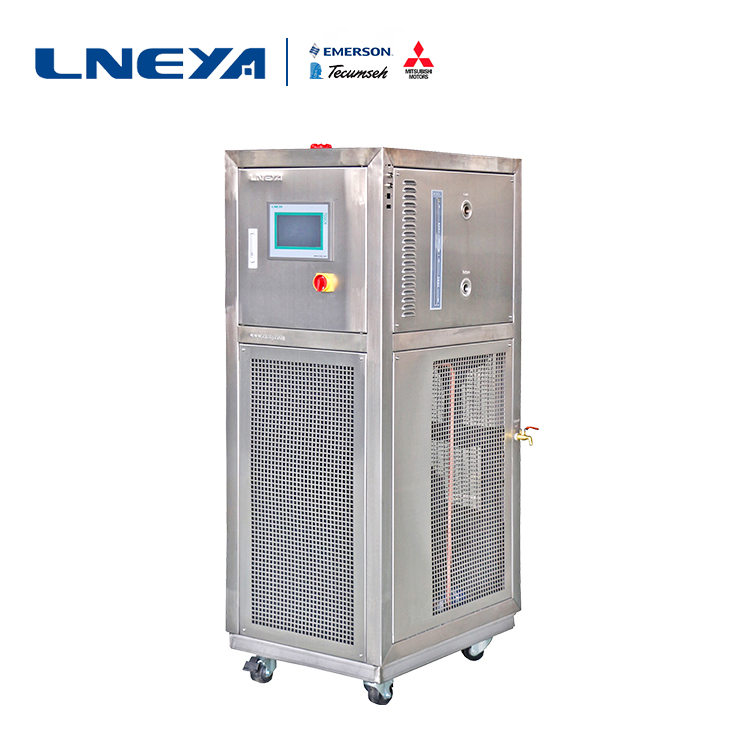

Manuale della macchina calda e fredda LNEYA SUNDI

The temperature range of the hot and cold machine ranges from -120 ° C to 350 ° C. It has superior performance and unique performance. It has high precision and intelligent temperature control. The high cooling power is from 0.5 to 1200 kW. High production stability and repeatability result. Functional alarm system and safety functions, using plate heat exchangers, ducted heaters to increase heating and cooling rates. The hot and cold machine adopts 7-inch, 10-inch color TFT touch screen grap...

Visualizza dettagli

Factors affecting cooling capacity during temperature control of battery test equipment

Battery Test Equipment Refrigeration System The greater the power of the battery test equipment compressor, the higher the cooling capacity. According to the size of the battery test equipment, the compressors of different types are selected. For example, the small battery test equipment is piston type, and the medium type is optional. Scroll type. When the water temperature of the battery test equipment (the evaporation temperature is different, the cooling capacity is different), the higher...

Visualizza dettagli

Importanza dei refrigeranti nei sistemi di prova delle batterie dei veicoli a nuova energia

If the flow rate of the refrigerant in the new energy vehicle battery test system is extremely small, the refrigerant will start to expand from the first expandable space at the rear end of the throttle valve. Most of the see-up of the rear end of the expansion valve is often due to lack of cooling. Or the expansion valve flow is not enough, too little refrigerant expansion will not use all the evaporator area, only the low temperature is formed locally in the evaporator, and some areas are r...

Visualizza dettagli

Descrizione del compressore del dispositivo di prova del calore umido ad alta e bassa temperatura

Different types of compressors for high and low temperature damp heat test devices often have an impact on price. When choosing, we should choose low-energy refrigeration compressors as much as possible. Now China is paying more and more attention to energy conservation and emission reduction, we must also make our own efforts. Doing this, and the loss of machinery is not much of a benefit to us, and the other is to choose less noise, so as not to affect our rest. High and low temperature dam...

Visualizza dettagli

Motor cooling system tests the effect of condensing temperature

The motor cooling system tests the condenser. Under normal conditions, the first half of the heat pipe is very hot, and its temperature has a slow and slow gradual decline in the balance of power. The heat sensitivity of the second half of the heat pipe is greatly reduced compared with the first half. It is because the refrigerant in the second half of the tube has gradually liquefied, and the condensation temperature and the supercooling temperature have been reached. When the motor cooling ...

Visualizza dettagli

Reasons for the decrease of heat transfer effect of vertical ultra-low temperature refrigerator

Se lo strato esterno di brina del frigorifero verticale a bassissima temperatura è troppo spesso o eccessivamente polveroso, la temperatura esterna dell'apparecchiatura può essere per lo più inferiore a 0, con conseguente bassa efficienza di trasferimento del calore dell'evaporatore. Poiché il frigorifero verticale a bassissima temperatura ha un'umidità relativamente elevata, l'umidità presente nell'aria è facile che si ghiacci sulla superficie dell'evaporatore, fino a congelare, il che influisce sull'effetto di trasferimento del calore dell'evaporatore. In ordine...

Visualizza dettagli

Semiconductor refrigeration temperature control table cooler operation instructions

The power supply switching of the control system of the transformer cooling system of the semiconductor refrigeration temperature control station uses the imported dual power automatic switching device. Its main function is automatic switching between the active and standby working power sources. When the common power failure occurs, it automatically switches to the standby power supply. When both power supplies are normal, the common power supply works and the standby power supply is in stan...

Visualizza dettagli

Multi-stage refrigeration system centrifugal compressor repair instructions

After the centrifugal compressor of the cascade refrigeration system is disassembled, the dimensions of each journal (cooperating with the impeller, bearing, coupling, etc.) are measured with an outer diameter micrometer to calculate the roundness and cylindricity deviation. The value should be Within the allowable range. When the tolerance is large, check if the straightness deviation of the spindle is too large. Place the spindle in the casing or place it on the top of the lathe so that the...

Visualizza dettagli

Battery test water cooler common knowledge description

Battery test Water-cooled air intake If there is no superheat, there may be a return air with liquid, and even cause a wet stroke liquid shock to damage the compressor. In order to avoid this phenomenon, a certain degree of suction superheat is required to ensure that only dry steam enters the compressor (the presence of superheat indicates the complete evaporation of the liquid refrigerant due to the nature of the refrigerant). However, the battery test water cooler has too high superheat an...

Visualizza dettagli Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore