Notizie

Caratteristiche strutturali del refrigeratore a ricircolo industriale

In the chemical reaction, there are strict requirements for the reaction temperature. It is necessary to raise the temperature to an appropriate temperature to carry out the chemical reaction smoothly. After the reaction, the temperature in the reactor must be reduced to room temperature. The existing heating system of the reactor is relatively simple, so the process of reducing the temperature in the reactor to room temperature takes a long time, and the thermal energy can not be used reason...

Visualizza dettagli

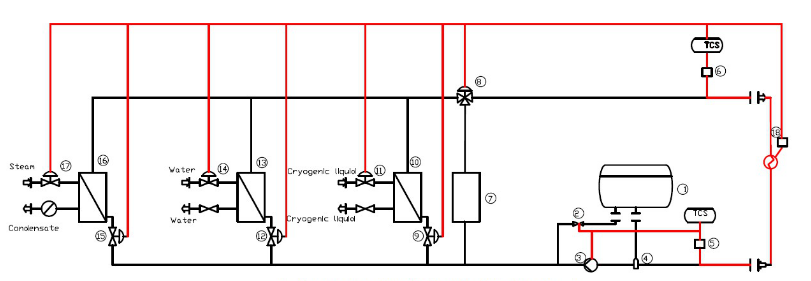

Sistema di controllo del processo di sintesi chimica Sistema di controllo della temperatura TCU

Today, let's talk about our DCS integrated control system (temperature and other control of synthetic process). Scalability: the system is an open system, which provides standard TCP / P data communication interface protocol, interface software and application software interface. It has good flexibility and scalability, and meets the requirements of continuously improving production scale for measurement and control ability. Security: the system has a permission mechanism to realize multi-lev...

Visualizza dettagli

Quali sono i punti principali per la manutenzione regolare del refrigeratore a ricircolo?

Recirculating chillers are used frequently in the industry, and the heat generating parts of various devices require recirculating chillers, so operating efficiency is very important. During the running time of the recirculating chiller, it is necessary to frequently check whether the cooling water pipe connection is safe and firm. Whether the flow, temperature and pressure of the cooling water are appropriate, so as not to affect the cooling effect of the recirculating chiller if the water f...

Visualizza dettagli

Quando scegliere il sistema di controllo della temperatura TCU?

First of all, we need to know that the reaction kettle generally needs to carry out the necessary temperature control along with the chemical reaction of the material itself. Through the temperature change of the circulating medium in the jacket or coil, the temperature of the material is controlled to achieve the target temperature of the material. For the temperature control of reaction kettles in the chemical and pharmaceutical industries, the selection of temperature control equipment is...

Visualizza dettagli

Four Key Points of Water Cooled Chiller Installation

The installation of water-cooled chiller can be carried out from four aspects: first, the installation of chiller, then the installation of water pipe, water pipe cleaning and equipment insulation. Do not underestimate the installation of this part, which will directly affect the safe and stable operation of the water-cooled chiller. Here are four key installation points. 1. Installation of water-cooled chiller (mainly foundation anti vibration device)We all know that a flat and spacious plac...

Visualizza dettagli

Cooling and heating temperature control system supporting glass reactor temperature control

my country's chemical industry has developed rapidly, and many enterprises have accelerated their stable development. In the chemical industry, the refrigeration heating temperature control system is matched with a glass reactor to control the reaction temperature. The cooling and heating temperature control system combined with the glass reactor is an ideal teaching and experimental temperature control equipment for modern fine chemicals, biopharmaceuticals and new material synthesis. The co...

Visualizza dettagli

Liquid Cooled Battery Pack BMS Test Cooling Water Circulator

As the temperature gradually increases, the use of the cooling water circulator for the BMS test of the liquid-cooled battery pack also gradually peaks. The rated power of the cooling water circulator for BMS testing of liquid-cooled battery packs ranges from several kilowatts to several thousand kilowatts. Nowadays, the production technology of BMS testing cooling water circulators for liquid-cooled battery packs has developed rapidly, and it is more guaranteed in terms of performance and st...

Visualizza dettagli

Quali sono gli interventi di manutenzione dei refrigeratori a glicole nel funzionamento quotidiano?

In the daily operation of the glycol chiller, if the maintenance is not in place, the cooling effect will be reduced. Therefore, in order to improve the operating efficiency, we recommend that you carry out the necessary daily maintenance. Refrigeration system inspection: Generally, after long-term use of ethylene glycol chillers, various problems will inevitably occur. In the event of a failure, the use of each part of the machine should be carefully checked, focusing on the refrigeration s...

Visualizza dettagli

Characteristics and applications of glycol chillers

Glycol chiller is applied to the cooling process of grinding machines, CNC machine tools and various precision machine tools, which can effectively reduce the thermal deformation of machine tools, improve the machining accuracy of machine tools and accurately control the oil temperature. Simply put, the output cold water temperature can be adjusted between 3-35 ℃. The water chiller is used to cool the forming molds of plastics, rubber and processing machinery, so that the products do not defo...

Visualizza dettagli

Vantaggi del refrigeratore a ricircolo per il raffreddamento a bassa temperatura

Low temperature cooling recirculating chiller is a kind of refrigeration using compressor, and the circulating pump provides cold source to maintain the temperature range from - 2 5℃ to 30 ℃. The refrigeration recirculating chiller has a space-saving vertical configuration and good heat dissipation effect. It can effectively control the external closed liquid loop when the temperature is far lower than 0 ℃. It is suitable for water, oil or other media of the manufacturer. All recirculating ch...

Visualizza dettagli Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore