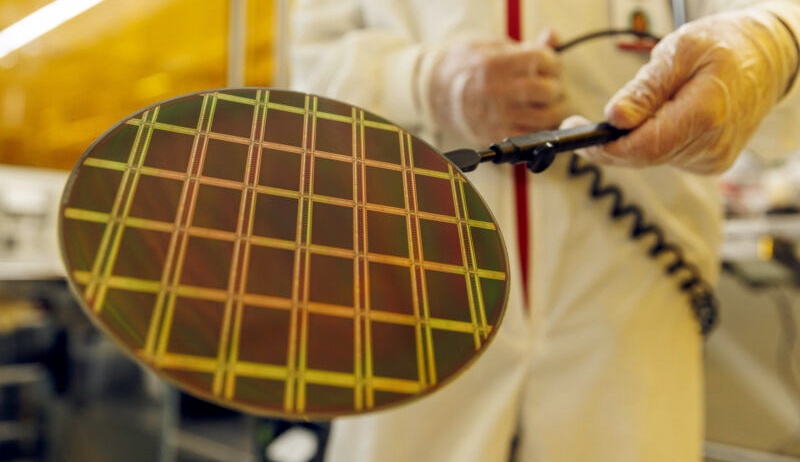

Why do special gases used in semiconductor manufacturing processes require chillers?

If you have any questions, please contact us

When using special gases in semiconductor manufacturing processes, a chiller is required, mainly due to the following reasons:

- Gas purity control: Special gases are used as raw materials in semiconductor manufacturing, and their purity is crucial to the performance of the final semiconductor device. Some special gases are prone to decomposition or react with impurities such as oxygen and water vapor at high temperatures, reducing their purity. The low-temperature environment provided by the chiller helps maintain the purity of gas during storage and transportation.

- Gas transportation and storage: Some special gases are easy to store in a liquefied state

Transportation, chillers can be used to cool gases to low temperatures, liquefy them, and facilitate storage and metering. Meanwhile, a low-temperature environment is beneficial for slowing down the natural evaporation rate of gases and reducing losses.

3. Process requirements: In semiconductor manufacturing processes such as chemical vapor deposition (CVD), physical vapor deposition (PVD), atomic layer deposition (ALD), etc., gas needs to go through a pre-treatment system, including a cooling system, before entering the reaction chamber to maintain gas transport at a specific temperature and prevent gas preheating or premature reaction in the pipeline.

4. Equipment cooling: Semiconductor production equipment generates a large amount of heat during operation, and requires a chiller to provide cooling for its internal gas delivery pipelines, reaction chambers, and other components to ensure that the gas maintains a stable temperature when entering and leaving the chamber. This is crucial for precise process control and product quality.

5. Safety considerations: Some special gases may become unstable or flammable and explosive at high temperatures. Using a chiller can reduce the risk of gas leakage accidents and ensure the safety of the entire process.

Therefore, the chiller is crucial for the storage, treatment, and use of special gases in the semiconductor manufacturing process, and is one of the key equipment to ensure the smooth progress of the semiconductor manufacturing process.

Request a quote

Forniamo consulenze gratuite e soluzioni complete 7*24

Raccomandazioni correlate

-

A cosa bisogna prestare attenzione quando si installa un sistema di raffreddamento della pila di ricarica CC?

922prestare attenzione quando si installa un sistema di raffreddamento della pila di ricarica in c.c.

Visualizza i dettagli -

Apparecchiature del sistema di controllo della temperatura di refrigerazione del laboratorio

1280I refrigeratori d'acqua da laboratorio, come dice il nome stesso, sono utilizzati principalmente nelle università e nei laboratori di ricerca scientifica. In particolare per il raffreddamento di piccole apparecchiature di laboratorio come spettrometro, spettrometro di massa, viscosimetro, rotazione,...

Visualizza i dettagli -

How to prevent the freezing pressure of the bearing quick freezing box from being too low?

1136In the refrigeration system of the bearing blast chiller, if the condenser installation is not in the enclosed space, the system's exhaust pressure (condensation pressure) tends to be lower in winter (or low temperature), which is often more commo...

Visualizza i dettagli -

Simulazione del controllo della variazione di temperatura nel sistema di termoregolazione del raffreddamento e del riscaldamento della casa.

810Il sistema di controllo della temperatura di raffreddamento e riscaldamento industriale è un'apparecchiatura di controllo della temperatura utilizzata nel processo di raffreddamento e riscaldamento del bollitore di reazione nell'industria farmaceutica e chimica. Quali sono le caratteristiche delle apparecchiature lneya?...

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore

Invia per la consultazione

Vi risponderemo entro 24 ore