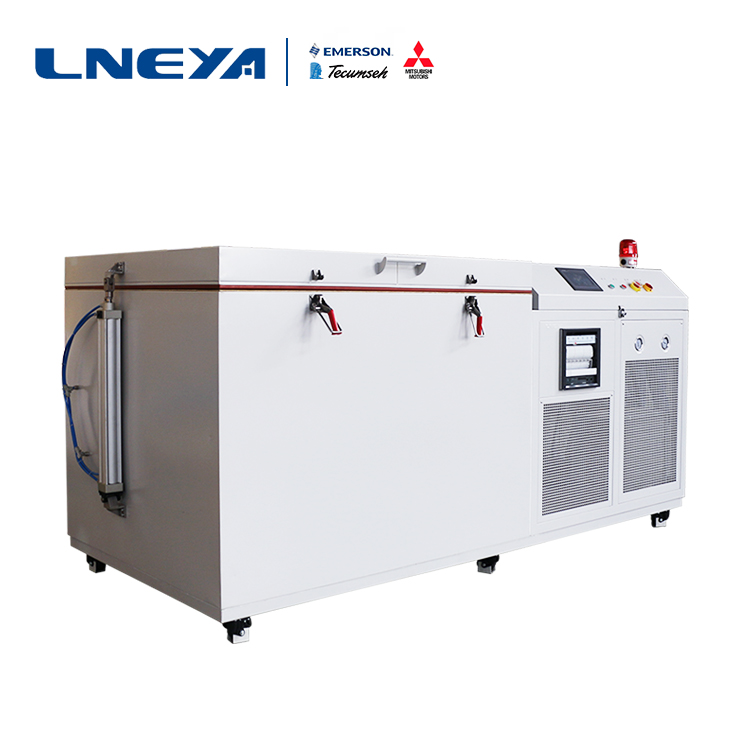

Come evitare che la pressione di congelamento della scatola di congelamento rapido dei cuscinetti sia troppo bassa?

In the refrigeration system of the bearing blast chiller, if the condenser installation is not in the enclosed space, the system’s exhaust pressure (condensation pressure) tends to be lower in winter (or low temperature), which is often more common in the north. For bearing blasters, this is also the case for other equipment.

The low condensing pressure of the bearing quick freezing box will make the expansion valve unable to obtain sufficient pressure drop at both ends, and it is difficult to supply the appropriate refrigerant to the evaporator. On the one hand, the cooling capacity of the refrigeration system will not meet the requirements, and the system will also be made. Frequent low-voltage alarms and other faults.

To this end, we can deal with the method of exhaust pressure controller. When the intermittent operation of the fan is simple and easy to use, and the technology is mature, the controller used is a pressure controller. This pressure controller can control the intermittent start and stop of the fan. When the pressure is too low, turn off the fan. When the pressure is too high, turn on the fan. Generally, on a small-capacity unit, use two or more fans, one of which is normally open, and the other fans are pressure controlled. The controller controls the start or stop of the fan by the level of the condensing pressure.

It is also possible to use a pneumatic control device to utilize a high-pressure refrigerant-driven piston-type damper. This control device can operate as a stable exhaust pressure as the fan speed controller; the main reason is that the inlet pressure of the expansion valve does not resemble a fan. Intermittent operation produces large fluctuations, and the louver device can be installed either at the air inlet or at the air outlet.

In addition, the condenser overflow device can also be used to increase the condensing pressure of the system by using excess refrigerant, and the condenser overflow device is used for warming or low temperature environment, and the large flow refrigerant is taken from the liquid storage device. It is sent to the condenser, and the excess refrigerant is used to increase the condensing pressure of the system, thereby avoiding the failure of the condensing pressure being too low at low temperatures.

LNEYA’s methods to prevent the bearing chiller from condensing too low pressure are still relatively high, and users can try it according to their own needs.

Raccomandazioni correlate

-

Aspects to be aware of when using an air-cooled all-in-one

1346The air-cooled all-in-one is in operation, unless it is necessary, please do not open the chassis door, otherwise the following adverse consequences may result. When the equipment is subjected to a high temperature test, it is very dangerous to bl...

Visualizza dettagli -

Typical application of refrigeration heating temperature control system

1345LNEYA Dynamic thermostatic control of cold and heat source of high pressure reaction kettle, dynamic thermostatic control of double layer glass reaction kettle, and dynamic thermostatic control of cold and hot source of double-layer reactor. Micro...

Visualizza dettagli -

High and low temperature alternating wet heat shock test box function description

1490Consumers need to pay attention to the performance of the high and low temperature alternating wet heat shock test chamber. LNEYA's test chamber is closer to the needs of the purchasing company. The high and low temperature alternating heat and hu...

Visualizza dettagli -

Knowledge sharing of high-power chiller pipeline cleaning

1367For many companies, due to the weak awareness of daily maintenance of high-power chillers, industrial high-power chillers have not been effectively maintained for a long time. If the industrial high-power chillers lacks the necessary maintenance, ...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore