Why is there air in the reactor temperature control system?

The impurity gas in the reactor temperature control system is to increase the condensing pressure of the refrigeration system, thereby increasing the condensing temperature, increasing the exhaust temperature of the compressor, increasing the power consumption, reducing the cooling efficiency, and possibly the exhaust gas temperature is too high. The carbonization of the lubricating oil affects the lubrication effect, and in severe cases, the refrigeration compressor motor is burnt.

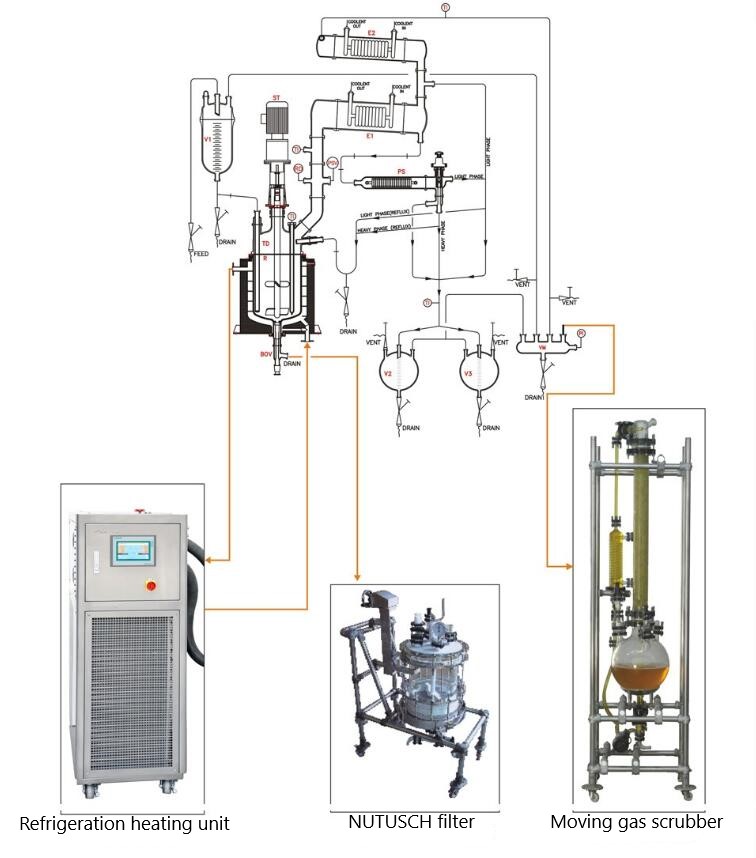

The gas generated in the reactor temperature control system may be leaking air. It may be when the refrigerant is filled or lubricated, the outside air is taken into the air, or the temperature of the reactor temperature control system is not tight enough to cause air to enter. Inside the system. In addition, gas is generated due to decomposition of the refrigerant oil, impure refrigerant, and corrosion of the metal material. Of course, Wuxi Guanya uses a fully enclosed circulation system on the reactor temperature control system to prevent this air from entering the reactor temperature control system.

In general, the gas in the reactor temperature control system is expressed in the reactor temperature control system compressor exhaust pressure and exhaust gas temperature rise, the pressure gauge pointer on the condenser (or reservoir) violently swings, the compressor The cylinder hair is hot, the condenser shell is very hot; the surface temperature of the evaporator temperature control system is unevenly frosted. When there is a large amount of gas in the reactor temperature control system, the ambient temperature cannot be lowered due to the decrease of the cooling capacity of the reactor. The machine runs for a long time, and even the high-pressure relay operates to stop the compressor.

If the reactor temperature control system has these gases, the pressure of the refrigeration system can be measured by a pressure gauge to compare with the saturation pressure at that ambient temperature. If the measured pressure is greater than the saturation pressure at ambient temperature, the system contains gas.

If the above-mentioned gases are found in the reactor temperature control system, it is necessary to eliminate these gases in time and solve the faults in time.

Raccomandazioni correlate

-

Come affrontare la scarsa dissipazione dei refrigeratori a bassa temperatura

1781Low temp chiller products contribute a lot to various industrial production, and at the same time, help to improve the labor efficiency of industrial production. With the development of China's economy and the improvement of production process req...

Visualizza dettagli -

Manufacturers of temperature simulation systems for chip testing analyze why chip testing is necessa

1597When users run the chip test temperature simulation system, they need to understand the chip test clearly. For this reason, the manufacturer LNEYA analyzes the relevant knowledge of the chip test and provides you with more detailed knowledge. Func...

Visualizza dettagli -

Quali sono i vantaggi e gli svantaggi dei circolatori per il riscaldamento a gasolio?

1752Il circolatore di riscaldamento ad olio a conduzione termica adotta una struttura a circuito completamente chiuso per agire direttamente sull'energia termica al mezzo riscaldato.I suoi vantaggi sono: (1) Grazie al continuo rinnovamento della superficie di trasferimento del calore, la perdita di calore è ridotta; (2)...

Visualizza dettagli -

Il motivo dell'esistenza del frigorifero criogenico nell'industria della produzione di parti di utensili

1366Il trattamento criogenico viene applicato agli utensili usurati, ai materiali delle fustelle e successivamente esteso agli acciai legati, al carburo cementato, ecc. Questo metodo è in grado di modificare la struttura interna dei materiali metallici, migliorando così la meccanica e la lavorazione...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore