Ultra-high temperature material cold and hot impact box refrigeration oil

The ultra-high temperature material impact test chamber test device has too much frozen oil in the evaporator, which can also cause insufficient cooling and cause slow cooling. The oil stored in the evaporator of the ultra-high temperature material impact test chamber test device can be directly judged by the hot and cold boundary line of the oil surface. If the oil level is too high, it should be released in time.

Some Freon and refrigerating machine oil dissolve each other. Therefore, when the refrigerant in the refrigeration system of the ultra-high temperature material impact test chamber test device is circulating, it is inevitable that the refrigerating machine oil will remain in the various components, and the residual oil in the heat exchanger will affect Heat transfer coefficient. Especially when the refrigerating machine oil enters the evaporator of the test device, if the structural design or installation is unreasonable, the ultra-high temperature material impact test device will only enter or reduce the refrigerating machine oil, so that the residual refrigerating machine oil in the evaporator is more The more you come, the more serious the heat absorption effect, and the lack of cooling capacity. If you don’t handle it at this point, the temperature will not drop. Therefore, you must carry out the oil draining work.

How to judge that the ultra-high temperature material impact test chamber test device has more refrigeration oil in the evaporation tube and affects the refrigeration is a difficult thing. In the case of the ultra-high temperature material impact test device, there is a significant anomaly, that is, the hoarfrost on the evaporation tube is sparsely pulled, incompletely formed, and is defrosted, if there is no other fault, then It is likely that there is too much residual refrigeration oil in the evaporator tube. To remove the freezer oil in the evaporator of the ultra-high temperature material impact test chamber test device, it must be removed, purged and dried. For the tube type evaporator, it is inconvenient to disassemble, the inlet of the test device evaporator can be blown with compressed air, and then the tube is baked with a blowtorch.

There are also many types of evaporators for the ultra-high temperature material impact test chamber test device. Once there are more refrigeration oils, we need to solve them in time.

Raccomandazioni correlate

-

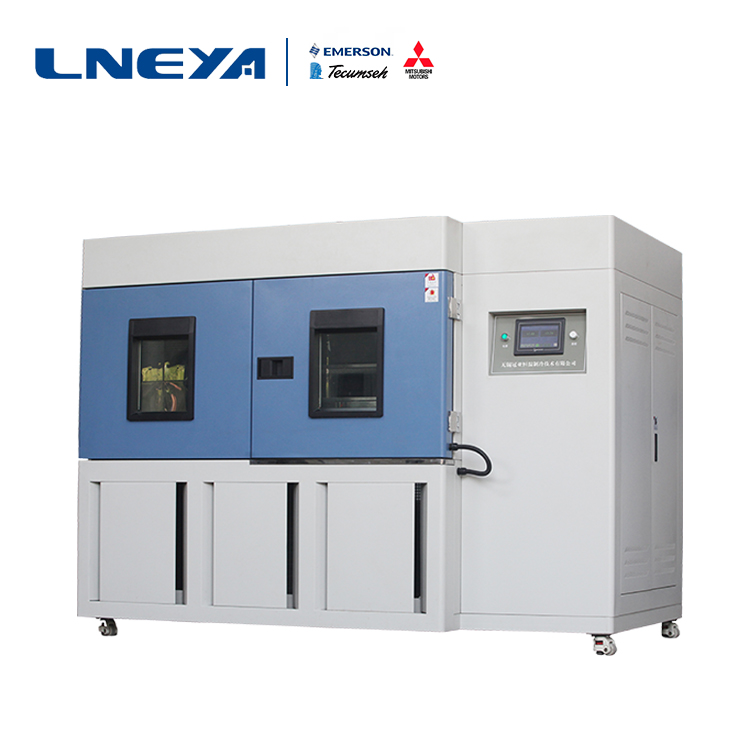

Part of LNEYA Equipment Function Introduction

19441.1.1 The industrial chillers(SUNDI series) is applied to cooling and heating the reactor, especially suitable for the process of heating and exothermic process. It can control the material temperature in the reactor, can choose the program contro...

Visualizza dettagli -

Diverse funzioni del refrigeratore di raffreddamento e riscaldamento del reattore sulla temperatura

1548Il refrigeratore di raffreddamento e riscaldamento del reattore è un tipo di macchina frigorifera, in quanto il suo componente principale utilizza un compressore a vite, che può essere chiamato il refrigeratore a bassa temperatura del reattore dal suo nome, ed è ampiamente utilizzato nel settore industriale ...

Visualizza dettagli -

Tester lineare a rapida variazione di temperatura Istruzioni per lo svuotamento e il riempimento

1740Prima di avviare il tester lineare a variazione rapida di temperatura, verificare se sono state adottate le misure di protezione necessarie, quali protezione antincendio, protezione, prevenzione delle perdite e altri strumenti. Controllare se l'alimentazione è stata predisposta secondo ...

Visualizza dettagli -

Semiconductor refrigeration temperature control table cooler operation instructions

1763The power supply switching of the control system of the transformer cooling system of the semiconductor refrigeration temperature control station uses the imported dual power automatic switching device. Its main function is automatic switching bet...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore