Introduction of temperature control equipment for cannabis extraction

CO2 is a unique solvent because its dissolving power can be changed by simply adjusting the temperature and pressure during the extraction process. When the pressure and temperature of CO2 are higher than 1083 psi and at 88F, CO2 is considered supercritical. If the temperature drops below 88F, CO2 becomes liquid, called subcritical.

Supercritical CO2 (SCCO2) extraction is a strong solvent that can extract all lighter (volatile oil, light wax) and heavier molecular weight (heavy wax, lipid, fat, paraffin) to produce very high The yield. At very high temperature (above 120F) and pressure (5000psi), it also extracts chlorophyll. Subcritical CO2 is a weaker solvent and usually only extracts lower molecular weights, and accordingly has lower yields and higher extraction times.

Using CO2 is the most effective and environmentally friendly method of extracting CBD oil.

Short-range distillation uses temperature and pressure variables to evaporate and re-concentrate based on the boiling point and molecular weight of the ingredients, allowing you to purify and concentrate the cannabinoid fraction from the original hemp or hemp extract.

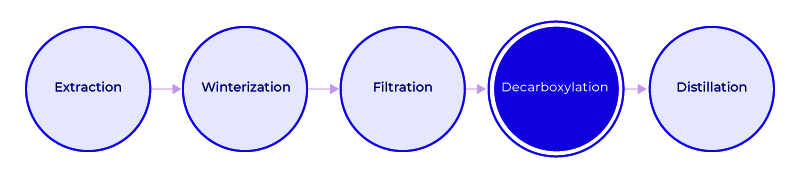

The oil extracted from the factory is considered crude oil. It contains undesirable ingredients such as fats, waxes and lipids. Before being sold as oil, it needs to be removed from the extract.

First the extract will be wintered, meaning the process of removing fat, wax and lipids. The extract was mixed with ethanol and placed in a deep freezer overnight. The mixture is then poured into a flask with a filter that captures unwanted elements. Then the ethanol needs to be removed, which is done using a rotary evaporator.

Decarboxylation is a chemical reaction that removes carboxyl groups and releases carbon dioxide (CO2). Heating the extract to a high temperature for a long time under vacuum will convert the acid cannabinoids into a neutral (activated) form, while also releasing carbon dioxide, residual solvents and other highly volatile components (terpenes) in the extract.

It can be seen from several processes of extraction that temperature control runs through all, whether it is high temperature and low temperature, cooling and heating. Lneya has rich experience in ultra-low temperature, high temperature and low temperature development, and the research on high and low temperature rapid heating and temperature technology is at the international advanced level. The high-precision temperature control of the reactor is the international advanced single-medium control -90°C~+250°C continuous temperature control, and the high-precision linear control of the reactor material temperature. The temperature control equipment used for CBD and BHO extraction are ultra-low temperature LJLD series, low temperature cycle LT series, high and low temperature cycle SUNDISR series. Our equipment is designed to maximize output and efficiency. Extract more and spend less.

Raccomandazioni correlate

-

Workflow and Equipment Composition of Oil Refining and Dewaxing

1579The oil dewaxing process is based on the melting point difference between the wax and the oil and the solubility of the wax in the oil becomes smaller as the temperature decreases, and the crystalline wax is precipitated by cooling. Then through t...

Visualizza dettagli -

Quali sono i componenti del sistema dei vari dispositivi di distillazione?

12261. Un set completo di apparecchiature per la distillazione a percorso breve: include evaporatore a percorso breve, sistema di riscaldamento, sistema di alimentazione, sistema di raffreddamento, sistema di vuoto, unità di raccolta del materiale, ecc.

Visualizza dettagli -

Istruzioni per l'installazione del frigorifero a -220 °C

1576L'aspetto e il peso dei diversi modelli di frigorifero a 220 °C sono diversi, quindi anche l'installazione è importante. -Il frigorifero a 220 °C deve essere collocato in ambienti interni, in un luogo solido e piatto, per ridurre le vibrazioni...

Visualizza dettagli -

Description of Type Selection and Classification of 40GW Cryogenic Chillers

1633If different enterprises and different industries have different requirements for Wuxi Guanya 40GW cryogenic chillers, its model selection is also different. So it is better to have a clear understanding of the needs of the selection of 40GW cryog...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore