Temperature cycle failure analysis of single fluid heating refrigeration system

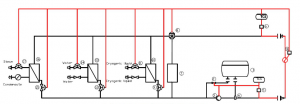

The performance of single-fluid heating and cooling systems of different manufacturers is different. LNEYA is committed to creating a high-configuration single-fluid heating and cooling system to solve the problem of cooling and heating temperature control for users. How to solve the problem of temperature cycle failure in single-fluid heating and cooling system? ?

The basic parameters of the temperature cycling of the single-fluid heating and cooling system are mainly six: 1 upper limit temperature; 2 lower limit temperature; 3 temperature change rate; 4 upper limit temperature holding time; 5 lower limit temperature holding time; In the single-fluid heating refrigeration system temperature cycle test, the uniformity of the gas flow in a single-fluid heating refrigeration system is an important parameter that will affect the temperature change rate of the product. The mechanism and sensitive components of temperature cycle induced failure: temperature cycling makes different materials with different expansion coefficients expand differently, causing peeling, cracking, and sensitive components such as paint coating.

The temperature cycling of the single-fluid heating and cooling system makes the joints that are screwed or riveted loose, and the sensitive components such as screws and riveted parts; the temperature cycle makes the press-fit joints with insufficient mechanical tension slack; the high-low temperature alternating test chamber temperature cycles make the material Poor solder contact resistance increases or induces an open circuit, and its sensitive components such as resistive components; temperature cycling causes contact corrosion and contamination, and its sensitive components such as alloy materials.

Therefore, for the user, the high-performance configuration of the single-fluid heating and cooling system is very important, the cheap single-fluid heating and cooling system is not necessarily easy to use, and the expensive single-fluid heating and cooling system will not go wrong. (This article is from the source network, if there is any infringement, please contact LNEYA to delete, thank you.)

Raccomandazioni correlate

-

Which industries are used for semiconductor device test equipment?

1772Semiconductor device test equipment is used more in the semiconductor industry. So, how much do you know about the applicable semiconductor conductors? The properties of this substance are still recommended to the user. In general, substances can ...

Visualizza dettagli -

Mechanical cold assembly equipment is dedicated to cold processing assembly of metal parts

1453Mechanical cold assembly equipment is a method of processing workpieces at temperatures below -130℃. Cryogenic treatment can significantly improve the toughness of the workpiece without reducing the strength and hardness of the workpiece. Mechanic...

Visualizza dettagli -

Sistema di controllo del processo di sintesi chimica Sistema di controllo della temperatura TCU

1773Oggi parliamo del nostro sistema di controllo integrato DCS (controllo della temperatura e di altri processi sintetici). Scalabilità: il sistema è un sistema aperto, che fornisce un protocollo di interfaccia di comunicazione dati TCP/P standard, un software di interfaccia...

Visualizza dettagli -

What are the conditions for the decarboxylation reaction? How to control the temperature of heating?

1879La decarbossilazione degli acidi aromatici è più semplice di quella degli acidi grassi. Ad esempio, l'acido benzoico può essere decarbossilato aggiungendo un po' di polvere di rame come catalizzatore in una soluzione di chinolina e riscaldando. Quando un gruppo fortemente elettron-rifiutante ...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore