Per quali reazioni sono adatti i reattori a microcanali?

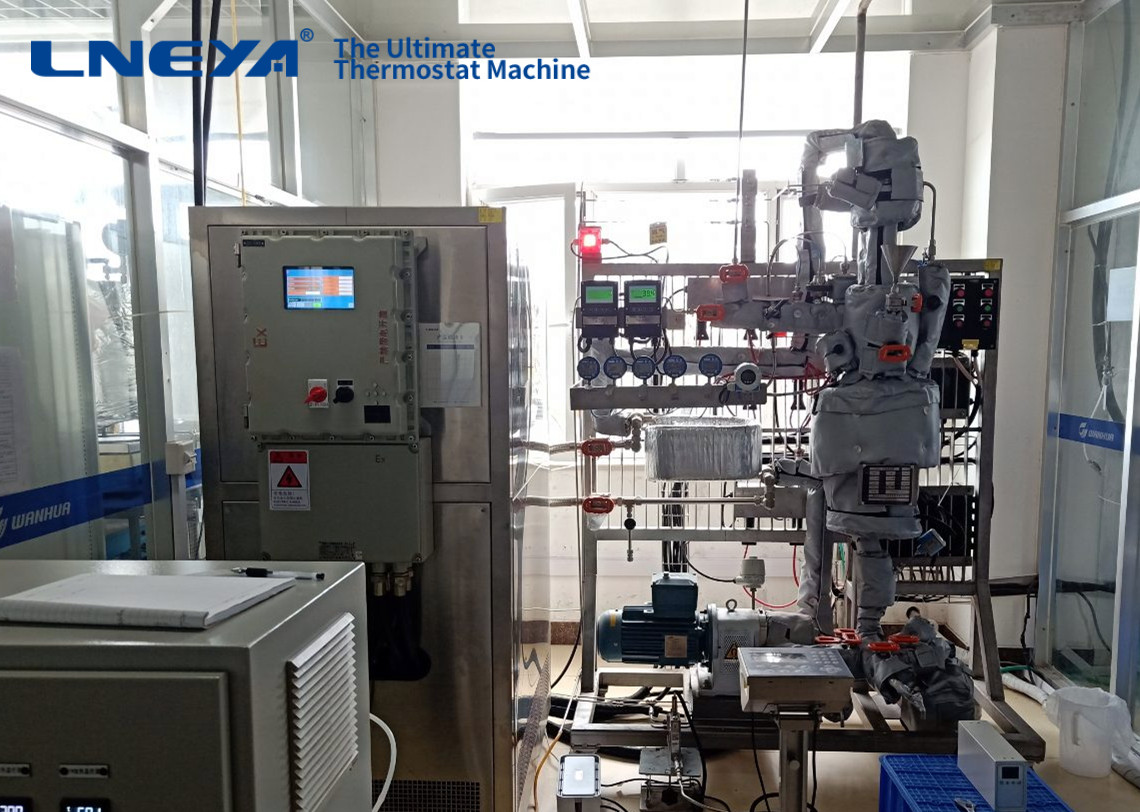

In recent years, micro-chemical technology has developed rapidly, and micro-channel reactors have attracted more and more attention. Microchannel reactors are manufactured with the help of special micromachining technology. They have the advantages of high mass transfer efficiency, good heat transfer efficiency, precise automatic control, small reaction volume and small amplification effect.

In the production process using p-cresol as raw material, a certain concentration of dilute nitric acid is generally added to the traditional kettle type reaction kettle, and the temperature of the reaction kettle is controlled at a low temperature, and then p-cresol is added dropwise at a certain speed. The temperature gradually increased, and the reaction was complete in about 2-3 hours. In the traditional reaction kettle, the reaction time is long, and as the reaction proceeds, the temperature is prone to side reactions, which reduces the yield of the product and makes subsequent separation and purification operations difficult.

In terms of structural characteristics, the current microchannel reactor can be used for the following types of reactions: widely used in various high-risk chemical reactor processes, used in liquid-liquid, gas-liquid, solid-liquid, and solid-liquid oxidation in the reaction. Reaction, nitration reaction, diazotization reaction, precipitation extraction application, phosgenation reaction, sulfonation reaction, ammoniation reaction, chlorination reaction, etc. Solve most of the difficulties and pain points of chemical reactors, metal material microchannel reactor, material selection: 316L stainless steel, 904 stainless steel, Hc, titanium, zirconium and tantalum materials, and design microchannel reactions with different structures for different reaction types device. The channel size of the microchannel reactor itself is very small, and it is easy to be blocked. Most of the reactors containing heterogeneous catalysts are not suitable for the use of microchannel reactors. In addition, the reaction system that is easy to generate larger particles is not suitable for the use of microchannel reactors. Corrosion issues cannot be ignored.

The reaction speed of the microchannel reactor itself is fast, but the reaction is violent, strong exothermic, and the product is easily destroyed. , significantly improve the heat exchange efficiency, improve the selectivity of the reaction, reduce the occurrence of side reactions caused by the problem of reaction temperature, and improve the yield of the product.

Raccomandazioni correlate

-

Elenco dei circolatori di refrigerazione e riscaldamento Descrizione del guasto di risonanza

1801Funzionamento del circolatore di riscaldamento a refrigerazione: Quando la temperatura del reattore, del reattore, dell'evaporatore rotante, dell'apparecchiatura di estrazione, ecc. del circolatore di riscaldamento a refrigerazione deve essere rapidamente aumentata o abbassata, l'apparecchiatura può...

Visualizza dettagli -

Quale tipo di refrigeratore può essere scelto per il raffreddamento di XRD?

1676Quale tipo di refrigeratore per il raffreddamento di XRD?

Visualizza dettagli -

Aumento della temperatura del bioreattore e apparecchiature di controllo della temperatura

1361Un bioreattore è un sistema di reazione in cui un microrganismo presente in natura o un microrganismo con una particolare capacità di degradazione viene inoculato in una fase liquida o in una fase solida. I due reattori attualmente più studiati sono i "reattori ad ascensore"...

Visualizza dettagli -

Nota di attenzione per il debug del sistema di raffreddamento a circolazione chiusa

1608Il sistema di raffreddamento a circolazione chiusa deve prestare attenzione ad alcuni problemi comuni durante la messa in servizio. Fare un buon lavoro di debug. I produttori di LNEYA ricordano agli utenti che solo quando sono pronti a lavorare possono essere sottoposti a un debug migliore. La preparazione...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore