Why do chemical raw materials require low-temperature chillers?

The main reasons for using low-temperature chillers in the production process of chemical raw materials are as follows:

Controllo della temperatura: Many chemical reactions are temperature sensitive and require precise temperature control to ensure reaction rate, selectivity, and product purity. Low temperature chillers can provide stable low temperature conditions to help maintain the temperature inside reaction vessels, crystallization tanks, or other equipment within a specific range, ensuring that chemical reactions proceed as expected.

Thermal management: Chemical reactions are often accompanied by a large amount of heat release, especially in exothermic reactions. If there is no effective cooling, the reaction system may overheat, leading to side reactions, catalyst deactivation, decreased product quality, and even safety accidents. The low-temperature chiller unit can promptly remove excess heat and maintain a stable reaction environment.

Crystallization optimization: In the crystallization process of chemical raw materials, low temperature helps to form purer and more uniform crystals. The chiller unit can optimize crystallization conditions, improve product purity and yield by precisely regulating temperature.

Material cooling and stability: Some chemical raw materials are prone to decomposition, deterioration, or polymerization at high temperatures. Low temperature chillers can cool the materials to ensure their stable properties and facilitate storage and transportation.

Equipment protection: High temperature operations may damage production equipment, such as sealing failure, pipeline expansion and deformation. The use of chillers can effectively protect equipment and extend its service life.

Safety production: Low temperature control can reduce the risk of accidents when dealing with flammable, explosive, or toxic chemicals, such as reducing the emission of volatile organic compounds (VOCs) to ensure production safety.

In summary, low-temperature chillers play a crucial role in the production of chemical raw materials, not only related to production efficiency and product quality, but also an important means of achieving safety production and environmental protection.

Raccomandazioni correlate

-

Efficient operation of high and low temperature integrated machine

1782To ensure more efficient operation of the high and low temperature integrated machine, you should select the appropriate type of equipment and solve the problem in time. The selection of high and low temperature integrated machines requires some p...

Visualizza dettagli -

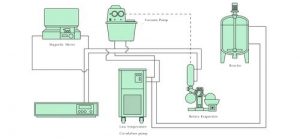

Low-temperature coolant circulation pump used with rotary evaporator

1898The chemical and pharmaceutical fields are the largest end consumer markets for cryogenic coolant circulation pumps. With the increasing demand for low-temperature coolant circulation pumps in this market, the application of cryogenic pumps in the...

Visualizza dettagli -

13p semi-closed air-cooled compression condensing unit failure warning instructions

1905The 13p semi-closed air-cooled compression condensing unit is used in industrial cold processing. After using it for a long time, some problems will arise, Wuxi Guanya (LNEYA) reminds. There is usually a high-pressure alarm on the 13p semi-closed ...

Visualizza dettagli -

Che tipo di sistema di controllo della temperatura è necessario per la preparazione dello striscio nell'industria farmaceutica?

1414Nell'industria farmaceutica, l'essiccazione a pressione negativa e la preparazione dello striscio hanno requisiti specifici per il controllo della temperatura e di solito richiedono dispositivi di controllo della temperatura precisi e regolabili per garantire la qualità del prodotto e la...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore