Closed hot and cold cycle machine compressor fault repair process

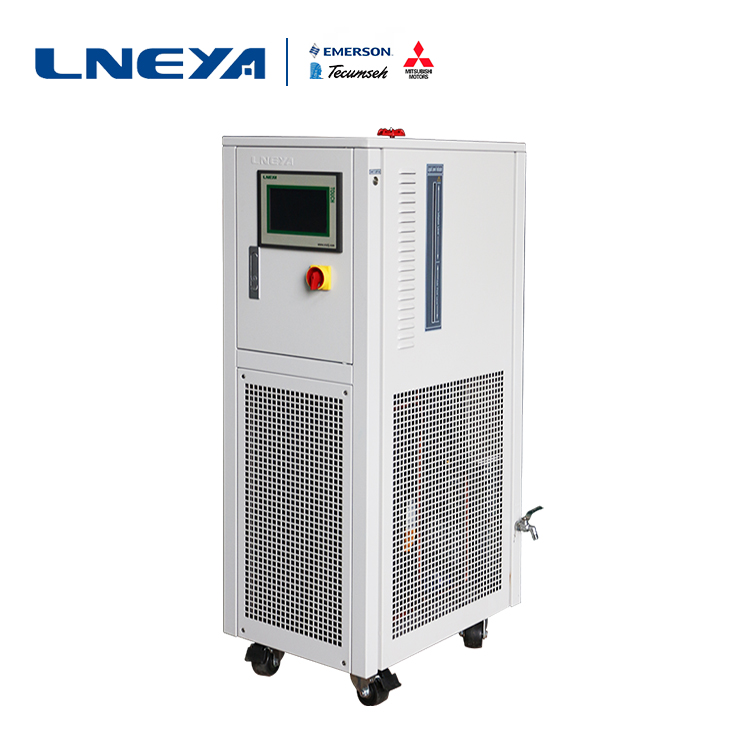

LNEYA’s closed-type hot and cold cycle machine adopts single-machine self-cascading refrigeration technology, and its compressor also uses the brand compressor, which is more stable in performance. Therefore, it is easy to choose a series of compressors with general performance. malfunction.

If the screw compressor is used in the closed type hot and cold cycle machine, the operation and maintenance process is very simple. Before the screw compressor of the closed type hot and cold cycle machine must be overhauled, if possible, the slide valve is unloaded to the “0” position. , normal shutdown, cut off the power. The compressor can be disassembled by cutting off the piping connected to the compressor and discharging the refrigerant and lubricating oil in the compressor. Be careful to develop good habits when disassembling. Parts of different parts should be placed separately and the necessary assembly marks should be made.

After removing the pipes, couplings and anchor bolts connected to the compressor of the closed type hot and cold cycle machine, the compressor is lifted to the workplace. Remove the suction filter, suction check valve, and remove the energy indicator. Remove the locating pin, remove the suction end cap in parallel, and take out the oil piston and balance piston. Note that when the positioning pin is taken, it can only be pulled out and cannot be pulled out. Be sure to take out the positioning pin first, then remove all the bolts to prevent the weight of the suction end cover from acting on the positioning pin and bend the positioning pin. Remove the shaft cover and remove the shaft seal. Be careful not to touch the moving and stationary rings, remove the positioning pin, remove the exhaust end cap, and remove the bearing gland, lock nut, washer, thrust bearing, adjusting pad, etc. To remove the locknut, use a special special tool and first open the lock tab of the lock washer. Mark them at any time and place them separately. After removing the compressor positioning pin, remove the exhaust end seat and use the special eye bolt to slowly and smoothly remove the active rotor, and do not collide with the body. At this time, the driven rotor rotates accordingly, and the driven rotor is taken out and the spool is taken out.

Wuxi Guanya (LNEYA) closed type hot and cold cycle compressor adopts Hanzhong, Bitzer, Copeland, Danfoss and other brands, and its performance is reliable. It is suitable for refrigeration, chemical and other industries, and has been highly praised by users.

Raccomandazioni correlate

-

Nel laboratorio farmaceutico si sceglie la pompa centrifuga o la pompa volumetrica?

1494Nel laboratorio farmaceutico, vengono utilizzate più apparecchiature di refrigerazione, poi come apparecchiature più comuni - pompe, principalmente pompe centrifughe, pompe volumetriche. Quindi, l'amico utente dovrebbe avere una migliore comprensione delle loro prestazioni...

Visualizza dettagli -

Unità di controllo della temperatura del reattore TCU con anello di controllo PID

1756L'unità di controllo della temperatura del bollitore di reazione LNEYA adotta il circuito di controllo PID, che trova applicazione in molti campi. L'unità di controllo della temperatura del bollitore di reazione tcu del circuito di controllo PID adotta un sistema di refrigerazione a ciclo completamente chiuso, con...

Visualizza dettagli -

The maintenance and maintenance of an ultra-low temperature refrigerator

1910The maintenance and maintenance of an ultra-low temperature refrigerator are very important for normal usage and prolonging its life. If the inaccurate temperature control often results in the damage of the protected objects, which will greatly af...

Visualizza dettagli -

Descrizione dettagliata della riparazione di valvole per macchine integrate per alte e basse temperature

2143The conventional high and low temperature integrated machine valve replaces the packing, and the main function of the packing is to prevent the working medium from leaking along the axial direction of the valve stem. In case of minor leakage, the ...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore