What are the functions of the reactor temperature control system?

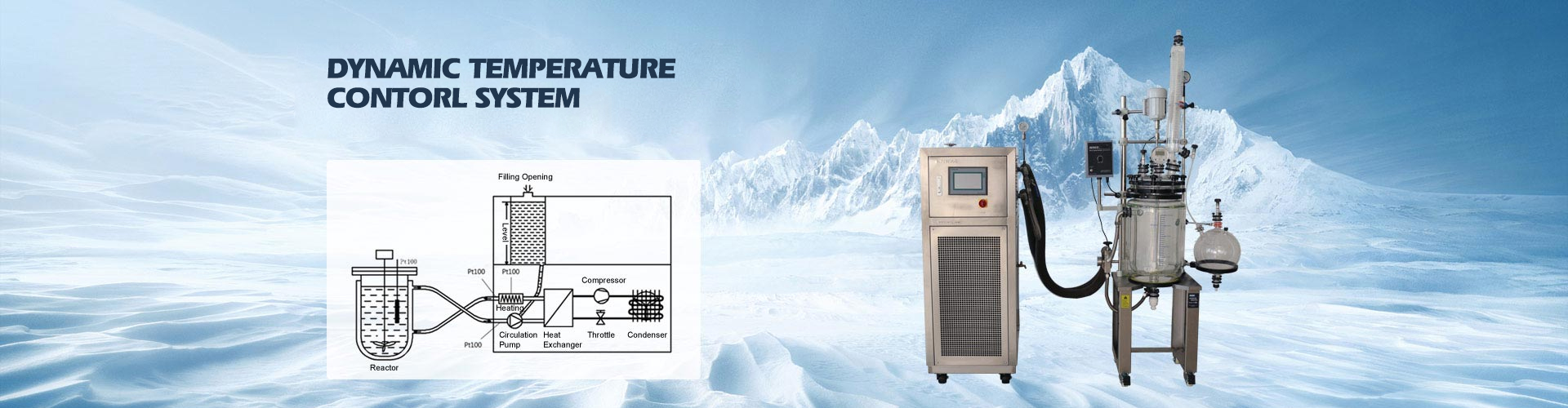

Il sistema di controllo della temperatura del reattore is equipped with various reactors for high and low temperature reflection of liquid and solid. The temperature control system of LNEYA reactor adopts fully closed circulation pipeline, which is efficient in operation and less polluted. So, what are the advantages of the reactor temperature control system?

LNEYA applies the technology to the reactor temperature control equipment, which can dynamically display the operating status of each equipment in real time, including real-time data changes of raw material tank weight, feed rate of various materials, valve operation on the equipment and corresponding temperature. The data display, etc., can simulate the flow chart shape, and the image is intuitive and easy to read.

The reactor temperature control system can display the real-time curve and historical data curve of each process parameter, and compare with the set process curve to guide the production process. The displayed historical curve can be saved for more than one year, which is convenient for users to view at any time. With the various process curves and ratios of the memory in the system, it is possible to issue control requirements to the PLC at any time according to the requirements of the production process, so that the production variety and the rapid change of the production process can be completed.

In addition, the reactor temperature control system can print a variety of production and statistical reports, with a very strong management function, the actual weight of each batch and the corresponding temperature, pressure data, etc., to print the data cost Accounting. The LNEYA autoclave automatic control system can perform manual and automatic interference-free switching operations. In order to enhance the performance of the whole system without losing flexibility, the system is equipped with computer operation and can be operated by touch screen, whether manual or not. Automatic or console button operation can be implemented very conveniently.

The reactor temperature control system uses an intelligent control technology to dynamically adjust the temperature by automatically adjusting the multi-parameters of the reactor jacket cooling water and material feed rate, thus allowing various physical processes and The chemical reaction process is more efficiently controlled.

The LNEYA reactor temperature control system uses a complete safety protection device to ensure safety problems in the production process of the reactor temperature control system to a greater extent.

(This article source network, if there is infringement, please contact LNEYA to delete, thank you.)

Raccomandazioni correlate

-

Piccola scatola di prova per urti caldi e freddi nota d'uso

1559La camera di prova per piccoli shock termici non è un prodotto antideflagrante (l'antideflagrante deve essere personalizzato); si prega di non utilizzarla in ambienti con gas infiammabili o esplosivi. Al fine di evitare piccoli shock termici, la camera di prova è difettosa, si prega di...

Visualizza dettagli -

Istruzioni per il test dei componenti delle società di ispezione dei trucioli

1561Con il continuo sviluppo dell'industria del collaudo dei componenti, sono nate aziende di collaudo dei chip e anche LNEYA ha introdotto apparecchiature per il collaudo dei chip. Il vettore di test della società di controllo dei chip è...

Visualizza dettagli -

Chemical process is inseparable from temperature control

1267Chemical process is inseparable from temperature control

Visualizza dettagli -

How to deal with the equipment failure alarm of the recirculating chiller

1917What to do if there is a failure and alarm during the use of the recirculating chiller equipment? In order to ensure production, such problems need to be resolved quickly. We must first understand the causes of failures and alarms, and adopt diff...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore