Prestare attenzione all'installazione del circolatore di raffreddamento ad alta e bassa temperatura.

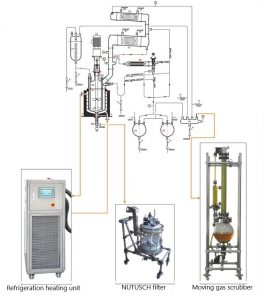

The high and low temperature cooling circulators can only be operated better if they are installed correctly. If the installation is not in place during the installation process, the high and low temperature cooling circulators will have certain hidden dangers in operation. What are the hidden dangers?

When installing the high and low temperature cooling circulator, it is necessary to pay attention to the refrigerant pipe entering the dust impurities, which will cause the cooling effect of the high and low temperature cooling circulator to decrease, and increase the wear of the high and low temperature cooling circulator compressor, thereby causing the high and low temperature cooling circulator group to be generated. Blockage, affecting the cooling effect. For the refrigerant pipe, it is necessary to pay attention to the refrigerant pipe leakage problem. If the leakage problem occurs, the overall cooling effect of the high and low temperature cooling circulator will be reduced. During this period, the long-term overheating operation of the compressor is extremely easy to make the life of the high and low temperature cooling circulator decline.

When the high and low temperature cooling circulator is installed, if the line is installed incorrectly, it will accelerate the damage of the electrical components, and may even cause the unit to operate in a chaotic manner, so that the individual control or centralized control cannot be realized, and the high and low temperature cooling circulator system cannot operate.

Wuxi Guanya LNEYA high and low temperature cooling circulator will produce condensed water during the process of cooling. The smooth discharge of condensed water will affect the installation of high and low temperature cooling circulators. The condensate pipes will be taken out from the internal machine to the outside or to the floor drain. Maintain at least >1% slope. When the discharge of the condensate line of the high and low temperature cooling circulator is insufficient, the unit may leak water and cause a short circuit of the power supply.

When installing the high and low temperature cooling circulator, it is necessary to prevent the outside of the equipment from being blocked within 1 meter. All the landing feet must be equipped with shock absorbing blocks to ensure that the high and low temperature cooling circulators operate normally. If the high and low temperature cooling circulator is improperly installed, the airflow will be short-circuited, and the protection switch action caused by the short-circuit of the airflow will cause the noise of the high and low temperature cooling circulator to affect the surrounding environment.

Therefore, the installation of high and low temperature cooling circulators should be careful to avoid improper installation and avoid these faults, and strive to make the high and low temperature cooling circulators operate effectively.

Raccomandazioni correlate

-

The safety of heat transfer oil in water-cooled chillers

1705In order to achieve better operating efficiency, water-cooled chillers need to choose branded heat transfer oil, but you need to pay attention to safe placement, a little carelessness will cause adverse effects. Although the heat transfer oil of t...

Visualizza dettagli -

Raffreddamento del serbatoio di stoccaggio refrigerazione refrigeratore

1364Il refrigeratore per serbatoi è un dispositivo utilizzato specificamente per raffreddare i materiali in un serbatoio per garantire che i materiali nel serbatoio siano conservati entro un intervallo di temperatura adeguato per mantenere la qualità e le prestazioni dei materiali. Questo tipo di refrigeratore...

Visualizza dettagli -

Quali sono i componenti che migliorano le prestazioni dei refrigeratori industriali?

1826I refrigeratori industriali sono attrezzature indispensabili nella produzione di LNEYA. Con il suo normale funzionamento, avremo una migliore efficienza lavorativa e una maggiore qualità del prodotto. Il sistema di refrigerazione di un refrigeratore industriale è composto principalmente da quattro...

Visualizza dettagli -

Come risolvere il problema del guasto al circolatore della pompa di refrigerazione?

1668I dispositivi di riscaldamento a refrigerazione sono necessari in molte applicazioni chimico-farmaceutiche e di laboratorio. Allora come risolvere il guasto del dispositivo di riscaldamento a refrigerazione è anche preoccupato di come risolverlo? 1. Guasto della pompa di circolazione La pompa...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore