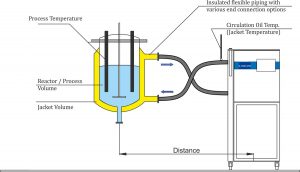

Battery test cooling device Chiller common configuration instructions

Under normal use, the battery test cooling device Chiller needs to be discovered in time when any part of the abnormality occurs. This requires a clear understanding of the basic configuration of the battery test cooling device Chiller.

Il battery test cooling device Chiller shell and tube condenser housing is normally the upper half is warmer and the lower half is warm. Under abnormal conditions, the entire housing is not too hot, and the original refrigerant amount is not enough. In another case, the entire housing is very hot due to insufficient cooling water or poor heat dissipation (scale in the water pipe). Under normal conditions, the casing condenser is very hot. The reason is that the cooling water is too small or the heat dissipation effect is poor. The other is that the outer surface of the casing is not too hot, because the refrigerant amount is insufficient.

Under normal circumstances, the battery test cooling device Chiller suction pipe feels cool and feels dew due to poor heat dissipation in the condenser, high condensation temperature or excessive refrigerant charge. Under normal conditions, the liquid tube is warm. Under abnormal conditions, the liquid tube is hot. The reason is that the condenser has poor heat dissipation, high condensation temperature or excessive refrigerant flow. Under normal conditions, the suction tube feels cool and feels dew. Under abnormal conditions, first, the suction pipe is cold and the dew is too much, so that the casing is exposed to a large area. The reason is that the refrigerant flow rate is too large, the liquid cannot be completely vaporized in the evaporator, and there is a liquid reflux phenomenon.

Battery test cooling device Chiller thermal expansion valve appearance temperature (including electronic expansion valve) Under normal circumstances, the lower half of the expansion valve body is very cool, and there is dew, the refrigerant flow is very dull. Under abnormal conditions, first, the valve body is relatively cold, the surface has more dew, and even frost, the refrigerant has a loud sound (gas flow). The reason is that the filter is blocked, or the refrigerant in the power box leaks, and the valve hole is closed. Under normal circumstances, the outer surface is very cold, and the condensation water drops continuously. The temperature of the inlet and outlet air is large, abnormal, the surface of the evaporator is not too cool, the dew is not much, or there is no condensation, and the refrigerant can be heard. The flowing sound is very loud, and the temperature difference between the inlet and outlet is small.

LNEYA battery test cooling device Chiller is equipped with brand accessories in the configuration, which has certain guarantees in safety and runs more smoothly and efficiently.

The above are the tips and instructions to be used during the use. You need to contact LNEYA when you need to know the device parameters or even the device video. Email address: sales@lneya.com

Raccomandazioni correlate

-

Stato attuale della camera di prova per il cambio rapido di temperatura a caldo e a freddo

1603Attualmente, i produttori di camere di prova a rapida variazione di temperatura, calde e fredde, stanno spuntando come germogli di bambù primaverili, ma ci sono diversi produttori che si distinguono per la qualità. Al momento dell'acquisto di una camera di prova, l'acquirente deve...

Visualizza dettagli -

Transmission powertrain cooling system with evaporator

1587The evaporator is one of the four major components of the refrigeration system, and it is the ultimate embodiment of the refrigeration effect and efficiency. The evaporator is generally designed and equipped by the transmission powertrain cooling ...

Visualizza dettagli -

Cosa determina il prezzo del circolatore di riscaldamento?

1362The price of heating cooling circulator is determined by raw materials, manufacturing overhead, technical cost, impacting on the final quotation. The heating cooling circulator is made of shell and internal parts. The shell is applied standard SUS...

Visualizza dettagli -

The cooling circulation system is used to collect the non-condensable tail gas in the distillation s

1565Most rectification towers are two-stage condensation. The first stage uses cooling water, mainly condensing the top steam, and the second stage uses chilled water or ethylene glycol, which is mainly used to treat tail gas and remove a small amount...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore