The cooling circulation system is used to collect the non-condensable tail gas in the distillation s

Most rectification towers are two-stage condensation. The first stage uses cooling water, mainly condensing the top steam, and the second stage uses chilled water or ethylene glycol, which is mainly used to treat tail gas and remove a small amount of light components. The exhaust gas is condensed. Therefore, the secondary condensation is very small.

Generally, a rectification tower (especially in the case of non-condensable gas, such as a vacuum tower, an atmospheric tower with gas dissolved in the feed, etc.), a two-stage condenser is placed on the top of the tower, and the first stage is cooled by cooling water. Part of the top steam is condensed, and the second stage adopts chilled water cooling to condense the light components in the tail gas as much as possible to reduce material loss. The reason for this is that the operating cost of chilled water is much greater than that of circulating chilled water, so it can be used as little as possible. The primary cooler uses cooling water to condense most of the easily condensable media, and the secondary cooler uses chilled water to condense the remaining small part of the exhaust gas that is not easy to condense. This can reduce the use of chilled water and save energy.

Distillation device, the device is divided into two stages of distillation, the first stage distillation condenser uses cooling water for condensation, while the second stage uses chilled water for condensation. The first stage adopts cooling water cooling to condense most of the top steam, and the second stage adopts chilled water cooling to recover the light components in the tail gas as much as possible to reduce material loss. The light components of the two stages are the same, but the amount of steam from the top of the second stage is smaller than that of the first stage. What is the difference between using chilled water to condense and chilled water to condense? Why do the primary and secondary condensers use different cold media for condensation?

Cooling water is circulating water, the temperature is generally 32-40 degrees. Low cost, easy to use, economical. Chilled water is low-temperature water produced by a low-temperature system. The temperature is generally below 20 degrees, and there are many grades to choose from. Chilled brine is relatively expensive, so the primary cooling will condense a lot of steam, and the secondary will condense the remaining steam.

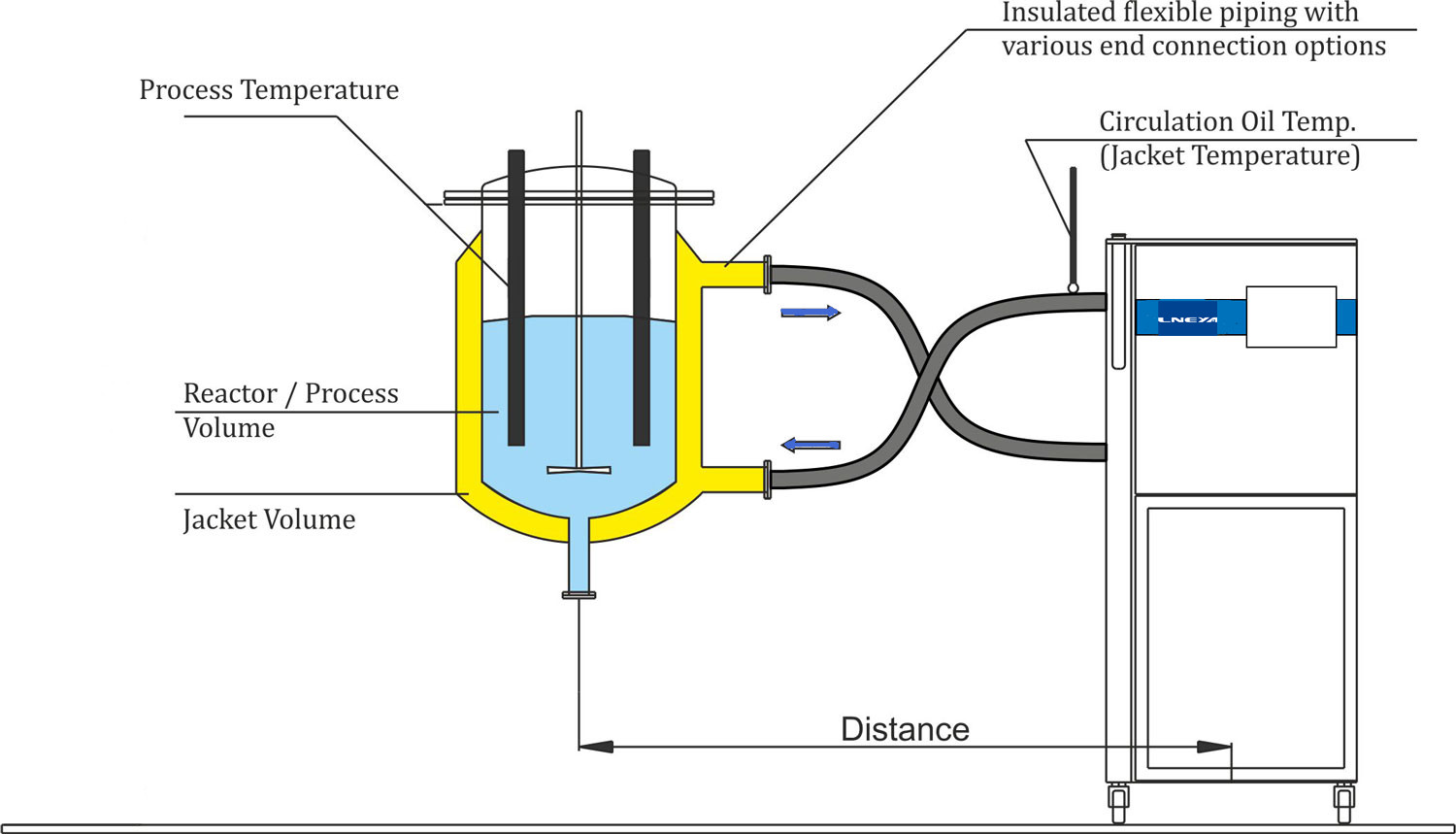

For the recovery of non-condensable tail gas components in the distillation system, cooling water and chilled water are indispensable, but this also invisibly increases the consumption of resources. The role of one or more water cooling systems is particularly important. The LNEYA cooling cycle system adopts secondary subcooling, which has a fast cooling speed, safe and reliable, and is used for rapid liquid cooling. It is widely used in petrochemical, medical, pharmaceutical, biochemical, freeze-drying, pharmaceutical, military and other high-tech industries. In order to save water resources, ethylene glycol-water mixture can be used for circulating refrigeration, and the circulation pipeline design is strictly designed to prevent circulating water pollution and extend the use time of circulating water.

Raccomandazioni correlate

-

La produzione di energia dall'idrogeno richiede refrigeratori di processo per il raffreddamento?

1317Process chillers are indeed needed in the hydrogen energy manufacturing process. Especially in the production of hydrogen, such as hydrogen production by water electrolysis, a lot of heat is generated in this process. The electrolyze...

Visualizza dettagli -

Principio di funzionamento dei refrigeratori d'aria industriali LNEYA

1585Il raffreddatore d'aria industriale è uno scambiatore di calore che utilizza l'aria per raffreddare il fluido caldo. Il fluido caldo nel tubo viene riscaldato attraverso lo scambio di calore tra la parete del tubo, l'aletta e l'aria esterna, solitamente fornita dal ventilatore. Il nostro...

Visualizza dettagli -

Il motivo dell'allarme di alta pressione dell'unità di controllo della temperatura integrata TCU

1530Quando si utilizza l'unità di controllo della temperatura integrata TCU, è necessario utilizzarla seguendo scrupolosamente le istruzioni. I problemi riscontrati devono essere affrontati tempestivamente. In generale, se si verifica un allarme di alta pressione da...

Visualizza dettagli -

How To Choose the Ultra Low Temperature Recirculating Chiller Expansion Valve?

1553Selection and installation of the expansion valve for ultra low temperature recirculating chillers: the selection of expansion valve plays an important role in the performance of the ultra low temperature recirculating chiller refrigeration system...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore