Come evitare il funzionamento improprio del circolatore di riscaldamento e raffreddamento?

When the user runs the heating and cooling circulator, the operation needs to follow the instructions. Then, how to avoid unsuitable operation?

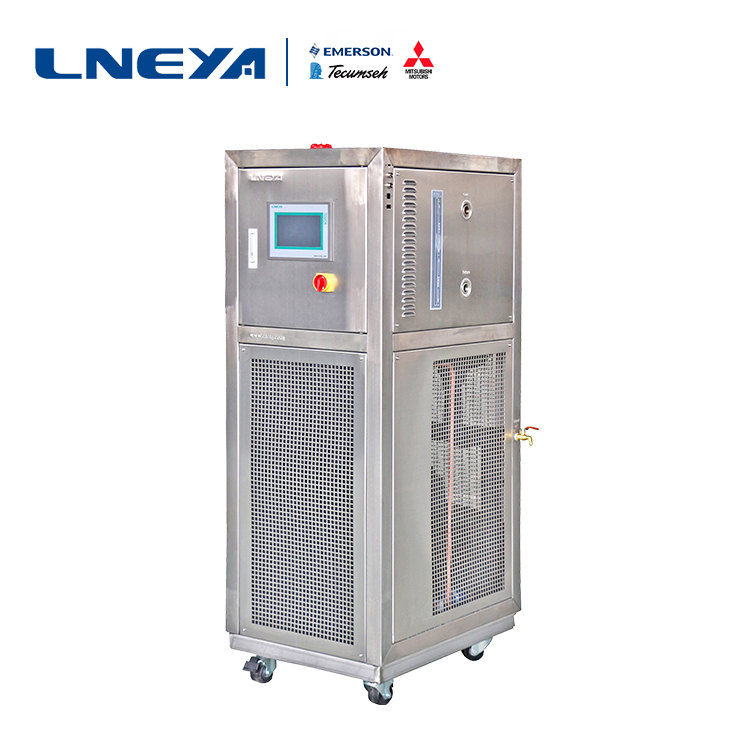

LNEYA heating and cooling circulator has multi-function alarm system and safety function. It uses plate heat exchanger and pipeline heater to increase heating and cooling rate. Large-screen touch screen graphic display, heating and cooling machine uses magnetic drive pump, no shaft seal leakage problem. Fully enclosed system, extending the life of the thermal fluid, a very wide temperature range, without the need to change the liquid medium.

Before the heating and cooling circulator is turned on, the inlet valve of the condenser on the unit that does not need to be opened is turned off to cause drowning, and a part of the cooling back water flows away from the condenser of the starting group, thereby reducing the cooling water in the condenser of the running unit. The flow rate causes the condensing pressure to rise. The operating current of the main unit increases. The cooling capacity of the unit is reduced, and the unit will be shut down seriously. It wastes electricity and reduces the cooling effect, and it is also easy to damage the equipment.

Due to the previous misoperation, the condensing pressure of the main engine and the temperature of the cooling water effluent rise, causing misjudgment to the operator. It is mistaken that the cooling water is not enough to open the condenser inlet valve and the cooling water pump outlet valve, and some also increase the cooling tower fan, resulting in increased power consumption of the pump and cooling tower fan. In addition, some users blindly added a cooling water pump. Although the addition of the cooling water pump can indeed reduce the cooling water temperature and the condensing pressure, after all, the power of one pump is wasted, so it is wrong.

The correct operation method of the heating and cooling circulator is that the unit condenser inlet valve is not required to be closed before starting to prevent drowning. Opening the heating and cooling unit will run the inlet and outlet valves on the unit condenser (the general outlet valve is normally open, the inlet valve is opened and closed as needed, and the condenser and evaporator are the same) to open the corresponding cooling water pump. Adjust the inlet and outlet pressure of the condenser to about 68.6 kPa (0.7 kg/cm). If the condenser inlet and outlet pressure gauges are swung too far, the cooling water system has air. The air should be vented until the pressure gauge indicates normal and continue to the next step.

During the use, do not handle all kinds of faults yourself, and avoid secondary damage caused by improper handling.

Raccomandazioni correlate

-

Un posto sicuro per i criocollettori nell'area di produzione

1461I criocongelatori sono utilizzati più frequentemente in estate. Alcuni produttori possono sostituire nuove apparecchiature, oppure alcune aziende si sono appena insediate nell'industria alimentare o in quella chimica, e i tipi industriali hanno bisogno di unità crioconservatrici per raffreddare ...

Visualizza dettagli -

Come pulire il sistema di controllo dell'aria?

1859Per rispondere alle esigenze dei due tipi di società del Paese, la protezione e la conservazione dell'ambiente sono diventate sempre più importanti. Pertanto, per prolungare la vita del prodotto, è ancora necessario avere ...

Visualizza dettagli -

Soluzione di raffreddamento a liquido per data center LNEYA Unità di distribuzione CDU raffreddata a liquido

1928Refrigeratore a liquido per centri dati LNEYA CDU

Visualizza dettagli -

The maintenance and maintenance of an ultra-low temperature refrigerator

1910The maintenance and maintenance of an ultra-low temperature refrigerator are very important for normal usage and prolonging its life. If the inaccurate temperature control often results in the damage of the protected objects, which will greatly af...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore