Advantages of laboratory low-temperature circulators

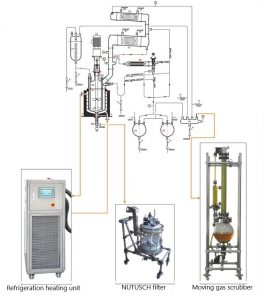

The laboratory low-temperature circulator can simultaneously provide constant temperature and current refrigeration, heating, and temperature control equipment. The laboratory low-temperature circulator has a reasonable structure, simple operation, and good stability.

1. The laboratory low-temperature circulator uses a compressor for refrigeration, which consumes energy and improves the exhaust temperature. The refrigerant then exchanges heat with the surrounding medium under the right conditions, transferring the heat to the surroundings. If adiabatic expansion is carried out again, the temperature will decrease.

2. The laboratory low-temperature circulator absorbs isothermal heat from high-temperature objects through an evaporator to reduce the temperature of the object to be cooled. This cycle is continuously carried out to achieve the purpose of cooling. The design of the laboratory low-temperature circulator refrigeration system uses energy regulation technology. Effective treatment methods can not only ensure the normal operation of the refrigerator, effectively control the energy consumption and cooling capacity of the refrigeration system, reduce the operating cost of the experimental box refrigeration system, and achieve a more economical state.

3. The laboratory low-temperature circulator absorbs the heat of the object to be cooled from the evaporator and evaporates it with steam. The compressor continuously extracts the steam generated by the evaporator.

4. The high-temperature and high-pressure steam compressed by the laboratory low-temperature circulator is sent to the condenser, where the cooling medium (such as water, air, etc.) releases heat and condenses into a high-pressure liquid. The pressure is reduced through a throttling mechanism to enter the evaporator. Evaporate again, absorb the heat from the cooled object, and circulate in this way.

5. After the laboratory low-temperature circulator mechanism heats up, the refrigerant changes its flow through a four-way valve. The flow direction of the refrigerant is exactly opposite to the refrigeration process. The refrigerant first passes through the evaporator, then returns to the condenser, and then returns to the compressor.

Raccomandazioni correlate

-

Come risolvere il problema del guasto al circolatore della pompa di refrigerazione?

1668I dispositivi di riscaldamento a refrigerazione sono necessari in molte applicazioni chimico-farmaceutiche e di laboratorio. Allora come risolvere il guasto del dispositivo di riscaldamento a refrigerazione è anche preoccupato di come risolverlo? 1. Guasto della pompa di circolazione La pompa...

Visualizza dettagli -

What kind of refrigerant is selected by industrial chillers in different industries?

1380The refrigeration temperatures required by different industries for industrial chillers are different, so the choice of refrigerants is also different. Therefore, when choosing an industrial chiller, you need to have a clear understanding of the r...

Visualizza dettagli -

Vocs exhaust gas condensation recovery unit refrigerant charging instructions

1662In the vocs exhaust gas condensation recovery process, the refrigerant is able to affect the operation of the vocs exhaust gas condensation recovery process, vocs exhaust gas condensation recovery treatment professional manufacturers reminded that...

Visualizza dettagli -

Laboratory dedicated chiller pressure description

1533The laboratory-specific chiller is one of the more popular equipments in the mechanical equipment industry. For this reason, the relevant pressure instructions have been specially compiled to help you better understand the laboratory-specific chil...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore