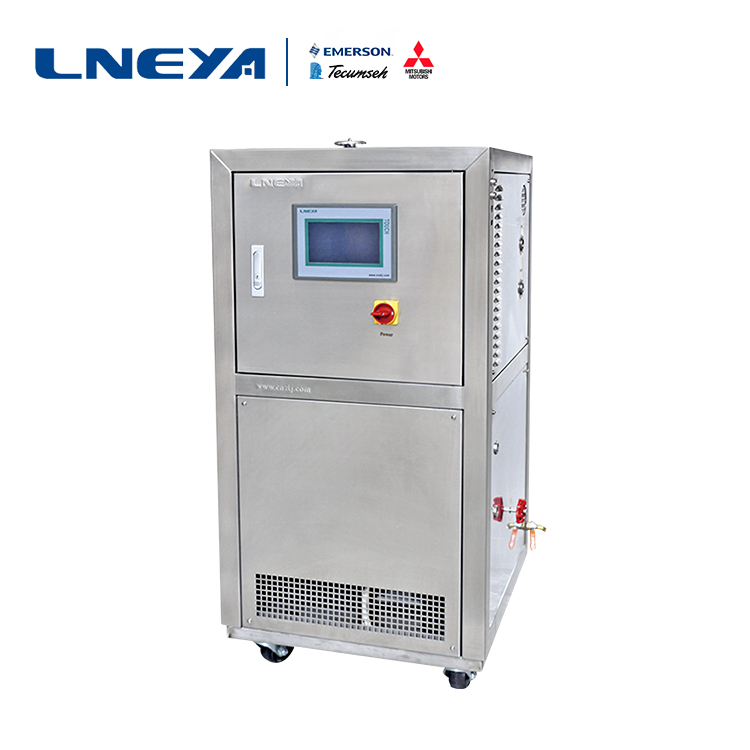

5P hot and cold water machine installation instructions

The 5P hot and cold water machine is used in various industries and is used for cold treatment. So what problems do you need during installation and maintenance?

If the 5P hot and cold water unit refrigeration compressor unit does not have vibration reduction installation, or the vibration reduction effect is not good, according to the installation specifications, the overall vibration damping device should be installed. If the vibration reduction is not standardized or there is no vibration reduction measure, the machine will vibrate severely. It is easy to cause the pipe to crack, 5P hot and cold water machine equipment is damaged, and even other equipment is damaged.

There is no or lack of oil return bend in the refrigerant line of the 5 hot and cold water integrated machines. When the pipeline conveying the refrigerant turns upward from the lateral direction, it must be made into a small bend that is first down and then upwards, that is, a U-bend, so that the 5P hot and cold water integrated machine pipelines are qualified only upwards, and cannot be directly Make a 90 degree steering upward, otherwise the oil in the system can not be returned to the compressor very well, and a large amount of deposition in the equipment, so that 5P hot and cold water machine and the entire system can not function properly, or even damage the equipment .

5P hot and cold water machine integrated machine refrigerant pipeline connection is not balanced, when the unit pipeline is connected to a group of multiple compressors, to make the oil return equal distribution to each compressor, the main pipeline interface must be set at multiple stations. In the middle position of the machine head, then set some branch lines to the two sides to balance the return oil into multiple compressor branch pipes.

The models and designs of the 5P hot and cold water machines of different manufacturers are different. When the LNEYA equipment is issued, the corresponding instruction manual will be attached to give the customer a detailed explanation.

Raccomandazioni correlate

-

Come risolvere il problema delle scarse prestazioni di raffreddamento del sistema di circolazione dell'olio di trasferimento del calore?

1643Alcuni sistemi di circolazione dell'olio a conduzione termica non sono più come prima dopo 3 mesi di utilizzo. A questo punto, si raccomanda di contattare il servizio di assistenza professionale per verificare l'alimentazione dell'utente e se l'apparecchiatura è a norma...

Visualizza dettagli -

Temperature control system for controlling integrated circuit chip test temperature

1607Advances in semiconductor technology have led to the development of next-generation electronic devices such as integrated circuits, which have more and more active components, higher circuit complexity, smaller area, and tighter wiring. These attr...

Visualizza dettagli -

Vocs gas condensation recovery unit processing instructions

1991With the continuous inspection of environmental protection, Wuxi LNEYA VOCS gas condensation recovery device has also received continuous attention from the public. Most chemical, pharmaceutical and industrial industries are urgently dealing with ...

Visualizza dettagli -

Analisi delle parti del refrigeratore a bassa temperatura

1825Il refrigeratore a bassa temperatura è un'apparecchiatura per il raffreddamento dell'acqua molto diffusa. Per questo motivo, quando lo si utilizza, è necessario prima comprendere il principio del refrigeratore d'acqua criogenico e dei suoi accessori, in modo da far funzionare il refrigeratore d'acqua criogenico in modo più efficiente...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore