What should do if the equipment of the thermal shock test chamber does not reach the set temperature

The choice of the manufacturer of the thermal shock test chamber is related to the quality of the thermal shock test chamber. Once the quality is set, the temperature setting of the equipment will not be closed. What should I do if I encounter the temperature setting problem?

The temperature set by the thermal shock test chamber is not up to the possibility that the heat exchange humidification tube is broken. You can either repair the factory or replace the new thermal shock test chamber directly. In the high temperature test, if the temperature does not change. When testing the temperature value, the electrical system can be inspected to eliminate the fault one by one, or the temperature probe may be broken, causing the device to not work when the water temperature is lower than the set standard temperature or 37 degrees.

The temperature and temperature of the thermal shock test chamber is too long or the heating tube is aging and damaged. When the actual water temperature is far below 37 degrees, the equipment has not worked, or the work is not working. If the temperature rises directly to cause over-temperature protection, the controller fails and the control instrument must be replaced. If the temperature is too high, you need to set the PID setting parameters first.

If the temperature rises very slowly, it is necessary to check the air circulation system to see if the regulating baffle of the air circulation is normally turned on. If the temperature of the thermal shock test box rises very quickly, check whether the motor of the air circulation is running normally. Because there is a time limit for use, so the running time is too long, it is inevitable that there will be some kinds of various faults, usually pay attention to regular maintenance and maintenance, generally can be largely avoided. If you encounter a large technical problem, you should seek solutions in time with the manufacturer.

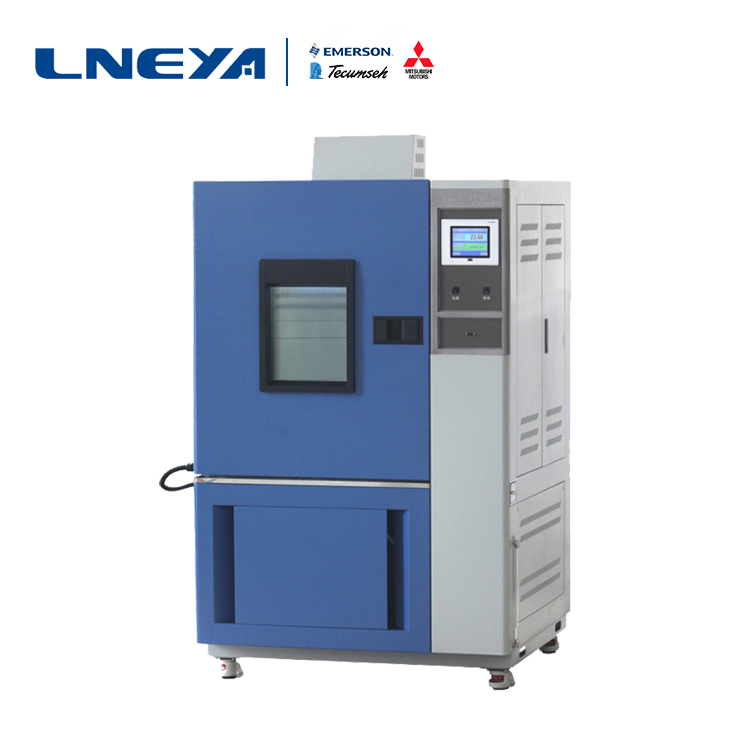

LNEYA thermal shock test box manufacturer is a professional hot and cold impact test box manufacturer integrating R&D, production and sales. It has more than ten years of experience in refrigeration and heating equipment production, and has reached cooperation with many domestic enterprises.

Raccomandazioni correlate

-

Points for attention in the selection of industrial heating and cooling machines

1083In food factories, pharmaceutical factories, biology, new material processing, and chemical plants, the raw materials in the reactor need to be cooled rapidly during the industrial production process involved in the reactor. In order to achieve th...

Visualizza i dettagli -

How to buy a laboratory chiller and maintenance knowledge?

890Laboratory chillers are products that provide constant temperature cold sources in industry and laboratories. If they cannot provide accurate cooling capacity, it will affect the operation of the equipment. Therefore, the laboratory chiller should...

Visualizza i dettagli -

How to Deal with the Poor Dissipation of Low Temp Chillers

1192Low temp chiller products contribute a lot to various industrial production, and at the same time, help to improve the labor efficiency of industrial production. With the development of China's economy and the improvement of production process req...

Visualizza i dettagli -

Analizzatore di qualità dell'acqua Hash chiller

794L'analizzatore di qualità dell'acqua Hash spesso richiede un controllo preciso della temperatura durante l'analisi della qualità dell'acqua per garantire l'accuratezza e l'affidabilità dei risultati di misura. I refrigeratori sono uno dei dispositivi più importanti che...

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore