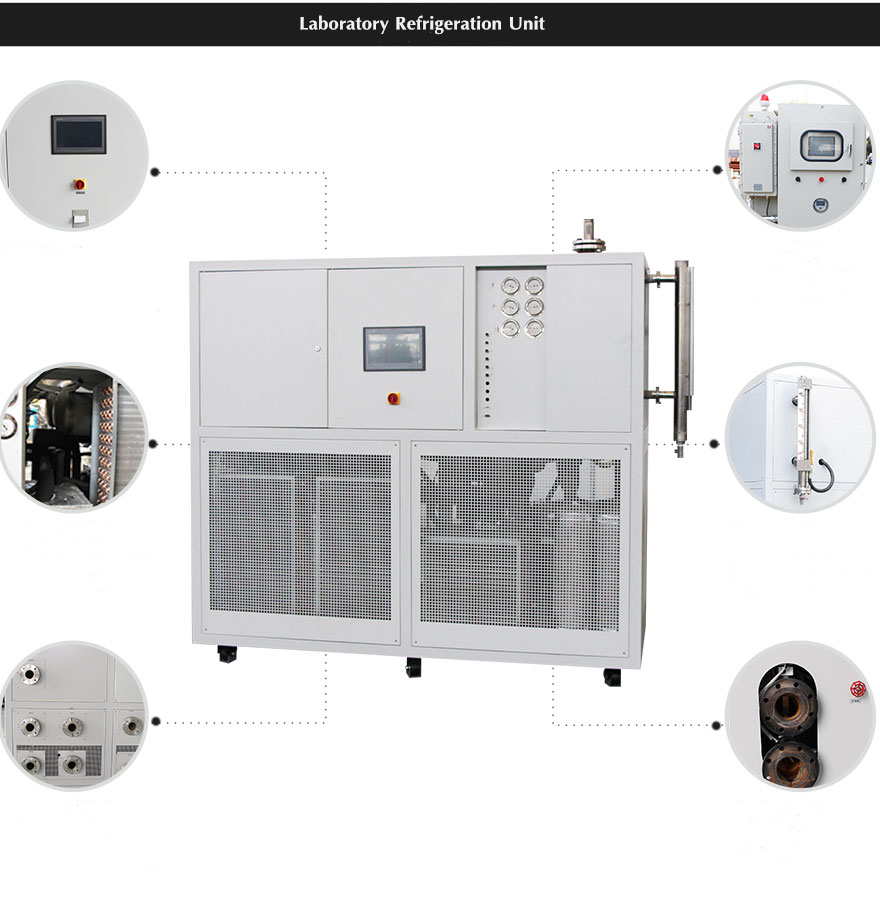

Routine maintenance points of special refrigeration units for laboratory instruments

Industrial refrigeration units dedicated to laboratory instruments are used more in the pharmaceutical and chemical industries, and care must be taken when using them.

The daily maintenance of the industrial refrigeration unit dedicated to experimental instruments is mainly reflected in the following aspects:

1. Condenser

The high-temperature and high-pressure Freon of the refrigeration system of the industrial refrigeration unit dedicated to the experimental instrument comes out of the compressor and enters the condenser, releasing a large amount of heat to the cooling medium and being liquefied by the cooling.

If the industrial refrigeration unit dedicated for laboratory instruments has been used for more than half a year, or the high and low pressure engines frequently fail, or the cooling capacity is reduced, please arrange a technician to clean the condenser. The fin condenser is generally cleaned with a high-pressure water gun. Be careful not to clean it sideways, which can easily cause the fin to fall over. Shell-and-tube condensers are generally immersed and circulated with descaling chemicals, and then the end cover is opened, and the pipes are cleaned one by one with a gun gun. Cleaning the condenser can significantly improve the refrigeration efficiency of the industrial refrigeration unit dedicated to laboratory instruments.

2. Compressor

Every time the compressor operating time of the industrial refrigeration unit dedicated to the experimental instrument exceeds one thousand hours, all details of the compression equipment should be checked. For example: whether the lubricating oil is normal; whether the running current of the compressor is normal; whether there is any abnormality when the compressor is running. Of course, the current refrigeration technology is quite mature, there are many sensors and protectors. When the unit alarms the fault, it should be repaired according to the fault location. When the compressor makes abnormal noise when it is running, it should be shut down for maintenance, mostly due to insufficient lubricant.

3. Refrigerant

The industrial refrigeration unit dedicated to experimental instruments is an indispensable equipment for industrial production now, and each unit is inseparable from the participation of refrigerant, so the lack of refrigerant will affect the normal operation of the machine and will appear The cooling capacity of the industrial refrigeration unit dedicated to the experimental instrument is insufficient, or the cooling temperature is very slow.

Routine maintenance cannot be ignored. Effective maintenance can keep the industrial refrigeration unit dedicated to laboratory instruments in an effective state of operation.

Raccomandazioni correlate

-

Istruzioni per la selezione del volume della camera per prove d'urto ad alta e bassa temperatura di piccole dimensioni

1233Quando il prodotto di prova (componenti, componenti, componenti o macchina completa) viene posto in una piccola camera di prova d'urto ad alta e bassa temperatura per il test, al fine di garantire che l'atmosfera intorno al prodotto di prova possa...

Visualizza i dettagli -

Vocs exhaust gas condensation recovery unit refrigerant charging instructions

1075In the vocs exhaust gas condensation recovery process, the refrigerant is able to affect the operation of the vocs exhaust gas condensation recovery process, vocs exhaust gas condensation recovery treatment professional manufacturers reminded that...

Visualizza i dettagli -

A quali settori possono essere utili i refrigeratori a bassa temperatura?

912Forse alcuni di voi non sanno molto dei prodotti di refrigerazione a bassa temperatura. Il refrigeratore a bassa temperatura è un tipo di apparecchiatura di refrigerazione professionale utilizzata nella produzione industriale. Negli ultimi anni, c'è stata una grande richiesta di diversi tipi di...

Visualizza i dettagli -

What is the thermal chuck temp control system used for semiconductor testing?

1054The integration of temperature control systems and heat cartridges is mainly used in the testing process of the semiconductor industry, serving the following key purposes: Wafer Acceptance Test (WAT): After the completion of semicond...

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore