Mettetevi in contatto con i nostri esperti di termoregolazioni farmaceutiche

Can’t find a suitable chiller? Or don’t know how to choose a chiller? Contact us now to get chiller details and prices

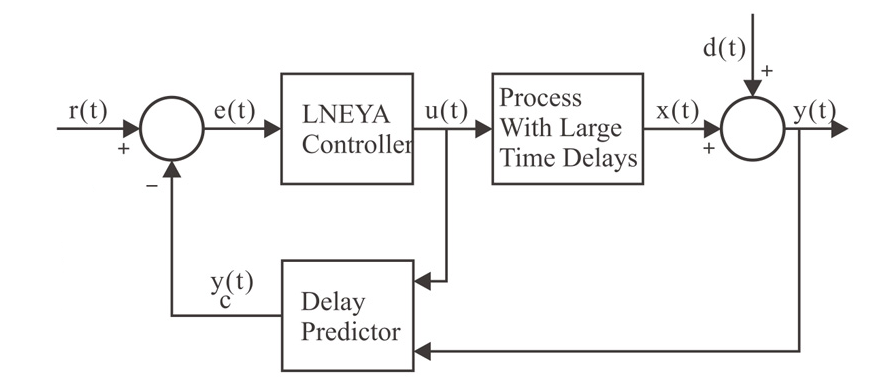

Il sistema di controllo termico è un dispositivo in grado di regolare rapidamente la potenza di riscaldamento e raffreddamento. Controllando lo scambiatore di calore del sistema, si ottiene un controllo preciso del processo di riscaldamento e raffreddamento. Quando è richiesto il riscaldamento, il sistema può aumentare rapidamente la potenza di riscaldamento per raggiungere rapidamente la temperatura richiesta del materiale; quando è richiesto il raffreddamento, il sistema può ridurre rapidamente la potenza di riscaldamento e scaricare rapidamente il calore attraverso lo scambiatore di calore per raffreddare rapidamente il materiale. Questa capacità di commutazione rapida rende stabile l'intero processo produttivo.

Sì. LNEYA vi assiste anche nell'installazione e nella messa in funzione. Dopo aver completato il processo di accettazione, i nostri tecnici dell'assistenza post-vendita forniranno una formazione tecnica fino a quando non sarete in grado di utilizzarlo. In caso di domande durante l'uso, potete consultarci per risolvere i problemi tecnici e noi vi forniremo assistenza online o offline, a seconda della situazione.

Inoltre, LNEYA promette che una volta acquistate le nostre apparecchiature, offriremo assistenza e manutenzione post-vendita a vita (con una garanzia gratuita di un anno, dopo la quale si applicheranno tariffe di manutenzione a seconda della situazione).

LNEYA raccomanda di selezionare una TCU farmaceutica in base alle seguenti prospettive:

- Requisiti di processo:

Se sono necessarie rapide variazioni di temperatura e compatibilità con i fluidi, si deve scegliere un tipo diretto.

Se è necessaria un'elevata precisione di controllo della temperatura o un'incompatibilità con i fluidi, scegliere un tipo di scambio termico secondario.

- Compatibilità media:

Quando il supporto è compatibile, il tipo diretto è più conveniente.

Quando il fluido è incompatibile, è più sicuro il tipo di scambio termico secondario.

- Intervallo di temperatura:

Per processi a temperatura medio-bassa o medio-alta, è adatto il tipo diretto.

Per i processi a temperature estreme, il tipo di scambio termico secondario è più appropriato.

- Requisiti di pulizia:

Per i processi con elevati requisiti di pulizia, il tipo di scambio termico secondario è più adatto.

- Spazio e manutenzione:

Se lo spazio è limitato o se si preferisce la semplicità di manutenzione, il tipo diretto è l'opzione migliore.

Se l'installazione e la manutenzione complesse sono accettabili, si può scegliere il tipo di scambio termico secondario.

Contatta LNEYA

Invia la tua richiesta e ti contatteremo entro 24 ore

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore