Sistema di raffreddamento e riscaldamento chimico - Produttore di sistemi di controllo dinamico della temperatura

In the pharmaceutical and chemical industries, cooling and heating system are widely used. As the developing of internet, many enterprises compete fiercely. The following will introduce the benefits of the LNEYA chemical cooling and heating system – dynamic temperature control system and what are the safe options.

Price is not the main factor for users to choose the chemical cooling and heating system – dynamic temperature control system. The main factor of choice is the suitable temperature technology implemented through the temperature control function. However, not each temperature control system of manufactures is same, the technology of different manufactures is different. Therefore, users need to choose carefully, considering whether the equipment is suitable for them, whether the quality is reliable and the operation efficiency is high.

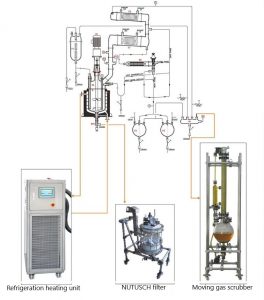

LNEYA has more than 10 years of production experience and spends a lot of human resources and investment on technical research every year. Based on the original technology, the company keeps innovating and researching and keeps learning advanced technology with a modest attitude, so as to create the chemical cooling and heating system – dynamic temperature control system that meets the market demand. It is suitable for high pressure reactor dynamic temperature control, double glass reactor dynamic temperature control, double reactor dynamic temperature control, micro-channel reactor dynamic temperature control, small temperature control system, steamed full system temperature control, material dynamic temperature aging test, combinatorial chemical dynamic temperature control, semiconductor equipment cooling and heating, vacuum dynamic temperature control and so on. The equipment adopts fully closed circulation pipeline, which will not produce oil mist in high and low temperature operation. The closed pipeline will not produce pollution and no heat-conducting medium will evaporate out at high temperature.

So how to choose a manufacturer? In fact, brand is strength.

Raccomandazioni correlate

-

Principali punti di manutenzione del circolatore frigorifero a bassissima temperatura LNEYA

1684Ultra-low temperature refrigeration circulators need to be maintained after a long period of operation, so what aspects should be paid attention to? Check and maintain the ultra-low temperature refrigeration circulator on time. It can find problem...

Visualizza dettagli -

All analysis of refrigerant changing process of industrial chiller unit

1553Refrigerant is an indispensable part of the refrigeration system of the industrial chiller. During the operation of the industrial refrigeration unit, the refrigerant constantly changes in the industrial refrigeration unit to achieve the cooling e...

Visualizza dettagli -

-

Product features of explosion-proof high and low temperature machine

1992LNEYA explosion-proof high and low temperature machine is a relatively temperature control equipment that can be used in the current heating and cooling system. It can be used for simultaneous cooling and heating. It can be combined with various r...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore