Precauzioni per l'installazione del compressore nella fabbrica dei refrigeratori a vite

When the operating conditions of the screw chiller factory restrict the compressor to be installed in a small enclosed space, its ventilation environment should be considered. It is necessary to add ventilation and exhaust equipment to facilitate circulation of air. The capacity of the ventilation and exhaust equipment must be greater than the exhaust volume of the compressor cooling fan, and the exhaust inlet position should be suitable for the hot exhaust outlet position of the compressor. Precautions for compressor installation of the screw chiller factory:

1. The compressor shall adopt a unit with large bearing capacity, and its operating speed and acceleration shall be limited within the permitted range.

2. Try to install the compressor of the screw chiller factory in a cool, clean and well-ventilated place to ensure that the air around the compressor is clean and the moisture content is minimized.

3. The air sucked by the compressor is not allowed to contain combustible gas and corrosive gas, so as not to cause internal explosion or internal embroidery.

4. Air-cooled machines should preferably have exhaust fans or air ducts to direct hot air out of the room to prevent hot air from circulating to the air inlet.

Commissioning of the new screw chiller factory shall be carried out by commissioning technicians designated or approved by the manufacturer. The compressor cannot work under the exhaust pressure higher than that specified on the nameplate, otherwise the motor will be overloaded and burnt out.

When the screw chiller factory is running, strictly check the running direction of the compressor. When reverse rotation is found, stop the machine immediately, cut off the power supply, switch any two of the three-phase lines, and restart the machine. Otherwise, the compressor of the screw chiller factory will be damaged (attention must be paid to each factory power supply overhaul!).

Raccomandazioni correlate

-

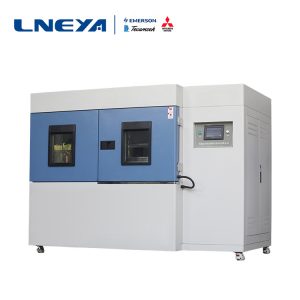

Treatment of insufficient exhaust gas in high and low temperature impact test chamber compressor

1772The efficiency of the high and low temperature impact test chamber during use is very important. If there is a shortage of high compressor exhaust, we need our LNEYA technicians to solve it in time. So, how to solve it better? The high and low tem...

Visualizza dettagli -

Characteristic Analysis of Air Cooled Industrial Chiller

1386I refrigeratori industriali raffreddati ad aria sono generalmente macchine integrali, cioè evaporatore, compressore e condensatore sono realizzati insieme. Per un refrigeratore industriale raffreddato ad aria di potenza leggermente elevata, la dissipazione del calore della ventola di raffreddamento del condensatore deve essere...

Visualizza dettagli -

How to deal with frosting in cryogenic refrigeration systems?

1621If the low temperature refrigeration system has been frosted, believing that some enterprises have met, then how should we deal with such situation? Are there any methods can solve this problem. Today, let's know something about it with LNEYA refr...

Visualizza dettagli -

Citazione di Camera di prova ad alta bassa temperatura

1457Quando gli utenti scelgono e acquistano camere di prova a bassa temperatura, molti produttori come Wuxi LNEYA spiegano i fattori di prezzo della camera di prova a bassa temperatura. Il prezzo della camera di prova a bassa temperatura è relativamente alto...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore