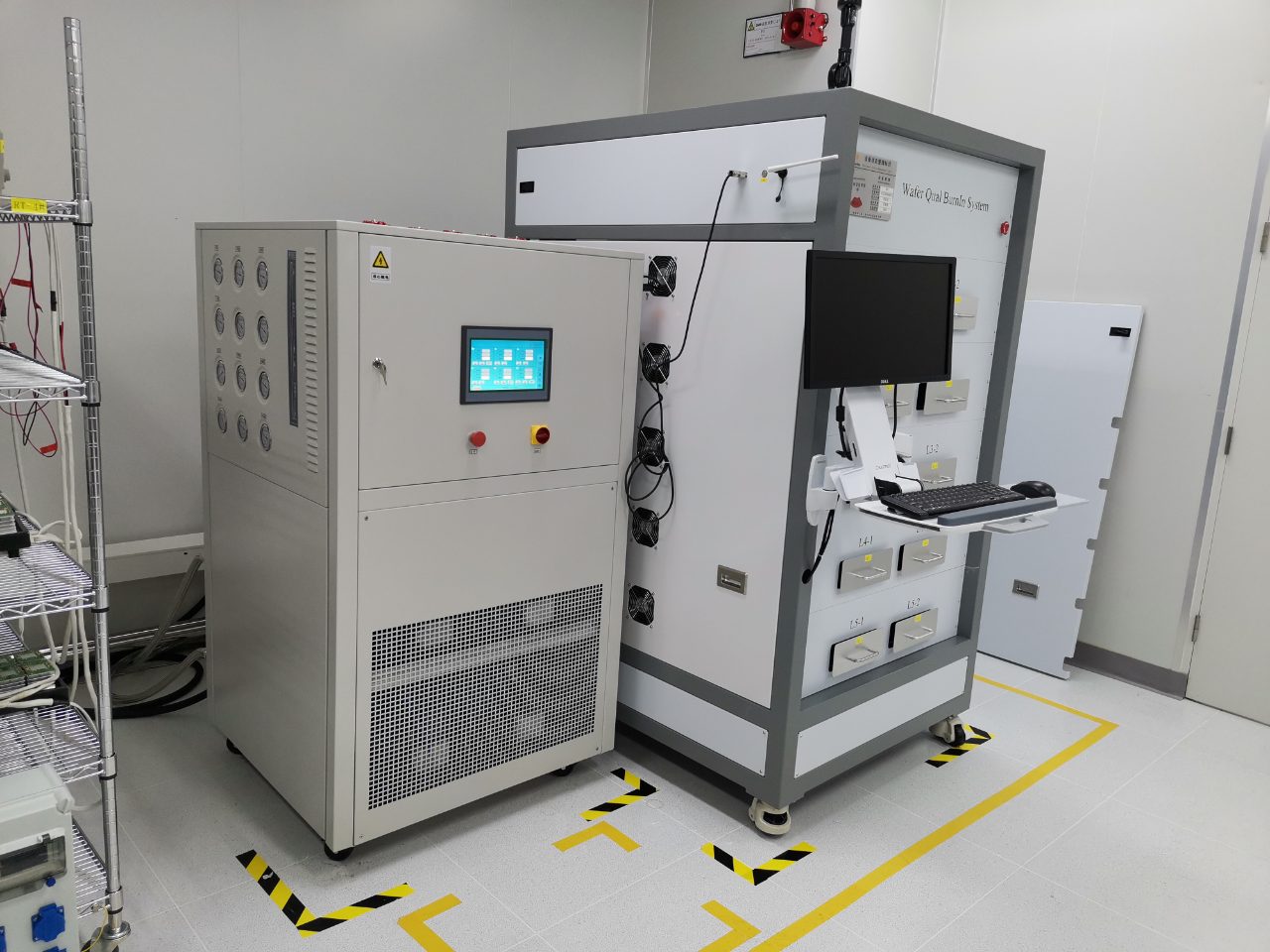

Risoluzione dei problemi di guasto del sistema di refrigerazione delle apparecchiature di prova per l'invecchiamento dei materiali a bassa temperatura

Regular maintenance work for the material low temperature and high temperature aging test system, and troubleshooting of the refrigeration system is also very important. Here are a few tips.

1. Exhaust at double high pressure, heat dissipation may be problematic.

When it is detected that the high and low pressure of the system are higher than normal, it is usually because there is air in the system or excessive refrigerant is added. At this time, it is necessary to re-evacuate and add proper amount of refrigerant to solve the problem. But there is another situation, that is, poor heat dissipation, especially when the ambient temperature is relatively high, which often results in worse heat dissipation. The cause of this failure is generally that the heat sink is blocked, dirty, and the speed of the heat dissipation fan is not enough.

2. Refrigerant with low pressure loss, otherwise the system will be blocked.

When the high and low pressures are both low, there are two possibilities:

(1) If the system is blocked, the blocked part will produce throttling, and there will be a significant temperature difference in the throttling part, and the problem can be found by feeling it with your hands.

(2) The leakage of refrigerant leads to insufficient refrigerant. This situation is more common. At this time, the material’s low temperature and high temperature aging test equipment detector must be used to find out the leaking location and perform replacement.

3. Replace the compressor with low pressure, high pressure and low pressure.

When the pressure gauge of the material low temperature and high temperature aging test equipment detects that the low pressure is higher than normal, and the high pressure is lower than normal, at this time, it is recommended that the chiller refrigeration cannot achieve the effect of the normal material low temperature and high temperature aging test equipment. The reason is likely to be wear in the pump, resulting in a drop in power. At this time, it is often necessary to replace the compressor to solve the problem.

4. There is water vapor in the meter shake system, so it must be changed when it is exhausted.

When the refrigeration system of the material low temperature and high temperature aging test equipment is working, if the pressure gauge needle keeps shaking, it means that the system has moisture. To solve this problem, it is generally necessary to re-evacuate, and the pumping time must be no less than 15 minutes. If necessary, the drying bottle needs to be replaced to drain the water in the system.

Raccomandazioni correlate

-

Istruzioni per la manutenzione della valvola di espansione delle apparecchiature di separazione a condensazione Vocs

1391Una volta che la valvola di espansione del dispositivo di condensazione e separazione vocs si guasta, se la soluzione non viene risolta in tempo, l'intero dispositivo di condensazione e separazione vocs potrebbe non essere disponibile. Pertanto, il guasto della valvola di espansione del dispositivo di condensazione...

Visualizza dettagli -

Trouble shooting method for refrigeration device of air-cooled chiller chemical reaction kettle

1511If air enters into the air-cooled chiller refrigeration unit system of the chemical reaction kettle, the impact will be many. Enter the air circulation system first, the pressure will rise, the heat dissipation effect of the condenser will also be...

Visualizza dettagli -

Detailed introduction of the motor control cooling system Chiller

2085With the continuous development of new energy vehicles, the motor control cooling system Chiller is also under continuous development. The new energy vehicle motor test special chiller can adaptively adjust the cooling capacity of the chiller acco...

Visualizza dettagli -

Refrigeratore per bollitore di distillazione da 200 l

1227Il refrigeratore per il bollitore di distillazione da 200 litri deve soddisfare due funzioni principali allo stesso tempo: una è quella di condensare il vapore di metanolo e l'altra è quella di raffreddare il materiale durante il processo di reazione. ...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore