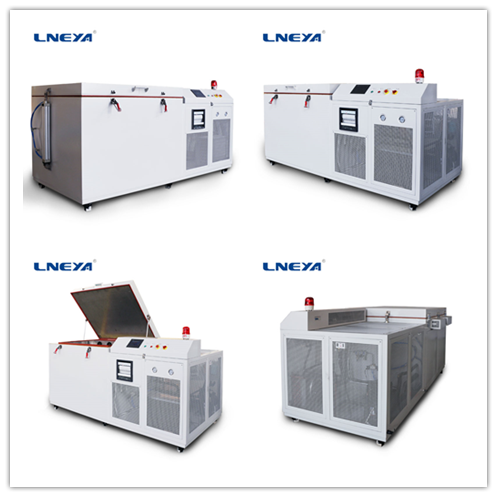

Descrizione del congelatore industriale a bassissima temperatura LNEYA

Il congelatore industriale a bassissima temperatura LNEYA è utilizzato principalmente nel trattamento industriale a freddo per far precipitare carburi uniformi, fini e dispersi sulla matrice della struttura metallica. La comparsa di tali carburi comporta un aumento significativo della resistenza all'usura e delle proprietà di attrito del metallo, nonché un aumento della durezza e un aumento diretto della durata dell'elemento soggetto a usura. Il prodotto ideale per sostituire l'azoto liquido.

Può essere utilizzato anche per la retrazione a freddo di manicotti di rame, cuscinetti, ecc. ed è ampiamente utilizzato nell'assemblaggio meccanico di precisione. È utilizzato nelle grandi attrezzature (automobili, grandi macchinari di ingegneria, parti di aerei, parti di attrezzature aerospaziali, parti di attrezzature militari, test a bassissima temperatura). Può essere utilizzato per il touch screen, il congelamento del display e lo smontaggio.

I diversi produttori hanno esigenze diverse, pertanto la maggior parte delle apparecchiature per la lavorazione del freddo viene realizzata in base ai requisiti. Al momento dell'ordine, si prega di fornire i seguenti indicatori:

1 carico massimo;

2 dimensioni della fodera: lunghezza, larghezza, altezza;

3 Tempo di raffreddamento a pieno carico fino al valore target.

Il congelatore industriale a bassissima temperatura LNEYA utilizza un riscaldatore elettrico in lega di nichel-cromo, il controllore stesso ha 2 protezioni, oltre alla protezione indipendente del limitatore di temperatura. Raffreddamento dell'apparecchiatura: (25° di temperatura ambiente, in condizioni di assenza di carico, da 0° a -110° per circa 1,5 ore); (25° di temperatura ambiente, in condizioni di assenza di carico, da 0° a -140° per circa 2 ore); il dispositivo avrà una velocità di raffreddamento leggermente diversa a causa delle variazioni della temperatura ambiente.

La modalità di controllo del dispositivo è il controller multifunzione ASET; touch screen a colori da 7 pollici, visualizzazione della temperatura di impostazione, della temperatura di misurazione e così via. La curva di temperatura registra la temperatura e i dati del disco U vengono esportati. Il formato è una tabella excel e la registrazione dei guasti. L'aria circolante all'interno dell'armadio: 2100m3/h; 2750m3/h; 4500m3/h..... Quando la porta viene aperta, la ventola di circolazione interna si spegne automaticamente e lo stato di apertura della porta viene visualizzato sul touch screen.

I compressori per tutti gli intervalli di temperatura sono di marche internazionali: Compressori Emerson Copeland, che utilizzano la tecnologia di refrigerazione automatica a cascata a compressore singolo.

Raccomandazioni correlate

-

La produzione di energia dall'idrogeno richiede refrigeratori di processo per il raffreddamento?

1318Process chillers are indeed needed in the hydrogen energy manufacturing process. Especially in the production of hydrogen, such as hydrogen production by water electrolysis, a lot of heat is generated in this process. The electrolyze...

Visualizza dettagli -

How to choose an industrial water chiller system

1765Want to buy an industrial water chillersystem? Want to buy a reliable industrial water chiller system? Want to buy ahigh-quality industrial water chiller system? How to buy?1. Process requirementsRegardless of equipment, LNEYA providesusers wit...

Visualizza dettagli -

Analysis of Common Faults in New Energy Vehicle Power Battery Test System

1433If the new energy vehicle power battery pack leaks, the general fault manifestation mode: the meter OK light does not light, the meter prompts to check the power system, the high voltage system leakage fault, disconnect the battery pack and the b...

Visualizza dettagli -

Come scegliere il dispositivo di riscaldamento e di raffreddamento del reattore?

1467Quando l'utente seleziona il dispositivo di riscaldamento e raffreddamento del reattore, se il dispositivo di riscaldamento e raffreddamento del reattore non è ben compreso, non saprà come iniziare la selezione, quindi come scegliere il riscaldamento e il raffreddamento del reattore è ...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore