Perché i gas speciali utilizzati nei processi di produzione dei semiconduttori richiedono refrigeratori?

If you have any questions, please contact us

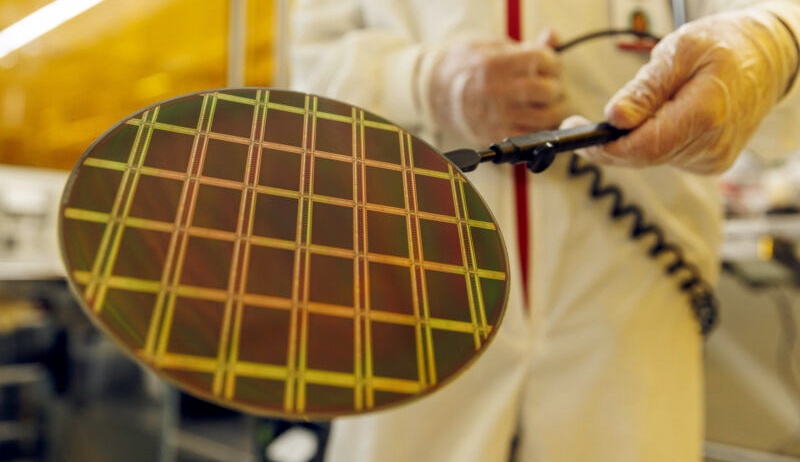

When using special gases in semiconductor manufacturing processes, a chiller is required, mainly due to the following reasons:

- Gas purity control: Special gases are used as raw materials in semiconductor manufacturing, and their purity is crucial to the performance of the final semiconductor device. Some special gases are prone to decomposition or react with impurities such as oxygen and water vapor at high temperatures, reducing their purity. The low-temperature environment provided by the chiller helps maintain the purity of gas during storage and transportation.

- Gas transportation and storage: Some special gases are easy to store in a liquefied state

Transportation, chillers can be used to cool gases to low temperatures, liquefy them, and facilitate storage and metering. Meanwhile, a low-temperature environment is beneficial for slowing down the natural evaporation rate of gases and reducing losses.

3. Process requirements: In semiconductor manufacturing processes such as chemical vapor deposition (CVD), physical vapor deposition (PVD), atomic layer deposition (ALD), etc., gas needs to go through a pre-treatment system, including a cooling system, before entering the reaction chamber to maintain gas transport at a specific temperature and prevent gas preheating or premature reaction in the pipeline.

4. Equipment cooling: Semiconductor production equipment generates a large amount of heat during operation, and requires a chiller to provide cooling for its internal gas delivery pipelines, reaction chambers, and other components to ensure that the gas maintains a stable temperature when entering and leaving the chamber. This is crucial for precise process control and product quality.

5. Safety considerations: Some special gases may become unstable or flammable and explosive at high temperatures. Using a chiller can reduce the risk of gas leakage accidents and ensure the safety of the entire process.

Therefore, the chiller is crucial for the storage, treatment, and use of special gases in the semiconductor manufacturing process, and is one of the key equipment to ensure the smooth progress of the semiconductor manufacturing process.

Request a quote

Forniamo consulenze gratuite e soluzioni complete 7*24

Raccomandazioni correlate

-

-

Manufacturer analysis – 90 ° C single-stage refrigeration system compressor common form

1878There are many types of compressors in the -90 °C single-stage refrigeration system. The most used ones are the piston refrigeration compressors. So, do you know which types? In the refrigeration system industry, the more commonly used refrigerati...

Visualizza dettagli -

Usage Details of High and Low Temperature Environmental Chambers

1692The enterprise users must have a certain understanding of the functions of the high and low-temperature environmental chamber after using them for a long time, but something detail of the high and low-temperature environmental chamber may still no...

Visualizza dettagli -

Diverse considerazioni importanti per le imprese quando si utilizzano i raffreddatori per riscaldamento

1744Oltre a quanto sopra indicato, le imprese devono prevedere una persona responsabile dell'avvio e dell'arresto dei frigoriferi, degli interruttori, delle riparazioni e della manutenzione. Le precauzioni per l'uso dei frigoriferi nelle aziende sono...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore

Invia per la consultazione

Vi risponderemo entro 24 ore