What are the applications of Industrial temperature control machine chillers?

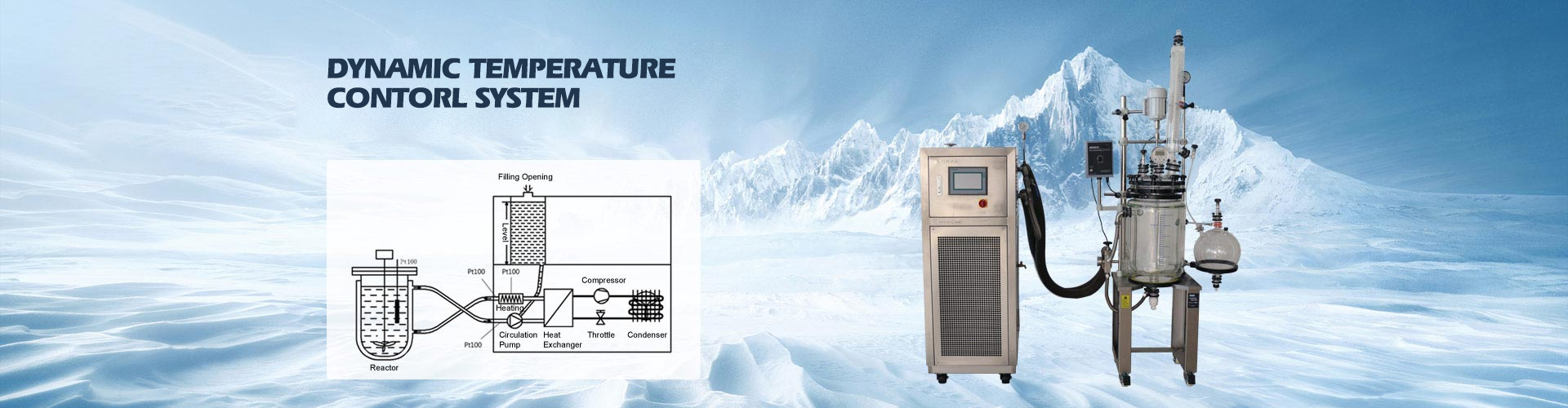

Industrial temperature control machine chillers are divided into oil-cooled and water-cooled according to the temperature and medium. The medium used is different for different temperatures, water can be selected for normal temperature, heat transfer oil for high temperature, and refrigerant for low temperature. According to the different cooling methods, it can be divided into air cooling and water cooling. Consider the ambient temperature of the industrial temperature control machine chiller, which affects the efficiency of the operation. If the temperature is higher, the effect of water cooling will be better; if the temperature is low, it is easy to freeze in winter, which has a great impact on the fluidity of water, so you can choose air cooling.

The two types of machines have certain requirements on the site. The water-cooled type requires water in the working environment, and uses water flow to exchange heat for cooling. If there is no water, it will not be able to work; the air-cooled type uses a fan to generate heat convection with the airflow outside the machine. . Good ventilation is required.

Industrial temperature control machine chillers can be used in multiple temperature test scenarios, such as in semiconductor production and testing of electronic devices, processes that require precise temperature control abound.

This includes, for example, the production of metal-organic compounds in the coating process of chemical vapor deposition for the production of LED wafers.

Two: The temperature control requirements of the new energy automobile industry are generally in the test bench and material testing links. All automotive components are subject to extreme temperature fluctuations.

Three: aviation heat sink experiment, component environment simulation test, evaporative cooling environment simulation test. Temperature simulation and temperature testing of materials are very important components in the aerospace field. Cyclic temperature change stress tests ensure that the components used do not have any failures, even under the extreme fluctuations of external conditions in space.

Raccomandazioni correlate

-

Test della temperatura di esercizio della batteria di un veicolo elettrico

1572Il normale intervallo di temperatura di esercizio delle batterie per veicoli elettrici è compreso tra -30 e 52 °C, mentre l'intervallo di temperatura di esercizio è compreso tra -46 e 66 °C, difficile da raggiungere con le batterie esistenti. Sebbene sia possibile adottare misure di riscaldamento...

Visualizza dettagli -

Metodo di selezione del liquido di congelamento 0℃~5℃ per il refrigeratore industriale a bassissima temperatura

1456Poiché i requisiti per la produzione di processo diventano sempre più elevati, i refrigeratori industriali a bassissima temperatura sono necessari per fornire liquido criogenico al di sotto dei 5 gradi o addirittura oltre i meno 100 gradi in alcuni processi chimici di sintesi, reattori...

Visualizza dettagli -

API exhibition LNEYA is brilliant

1870On October 14, 2020, the 85th China International Pharmaceutical Raw Materials/Intermediates/Packaging/Equipment Fair (API China for short) was grandly opened at Nanjing International Expo Center. The exhibition site was bustling and popular. LNEY...

Visualizza dettagli -

Quale modello di frigorifero industriale viene utilizzato per congelare i pezzi?

1556Il trattamento a freddo dei metalli consiste nel mettere un pezzo in metallo o in lega in un determinato mezzo, riscaldarlo a una temperatura adeguata e mantenerlo a questa temperatura per un certo periodo...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore