Come scegliere la tubazione per il recupero dell'adsorbimento per condensazione?

Dispositivo vocs di recupero dell'adsorbimento della condensa al momento della selezione, la sua configurazione di sistema deve essere chiara per poter acquistare con fiducia, quindi, i punti di attenzione della conduttura vocs di recupero dell'adsorbimento della condensa, come scegliere? Condensa...

Condensate adsorption recovery vocs should be as short as possible in the pipeline connection with the controlled substance, reduce bending, when the pressure of the circulation pipeline is too large, the pipeline pressure is insufficient, it will cause the pipeline, the reactor to crack, high temperature, The possibility of spraying low-temperature heat-conducting medium may cause injury, burns, frostbite and ignition of flammable materials, pollution caused by loss of reactants, property damage, and even poisoning of personnel.

The pipeline connection should be sealed and firm, and it has measures such as anti-vibration, grounding, rust prevention and pressure keeping. It can effectively prevent the pipeline from vibrating and corroding, causing cracks and leakage, and there is a danger of static electricity.

Condensate adsorption recovery vocs When connecting with controlled equipment, pay attention to the link of the pipeline, do not have the interface error, generally the liquid outlet corresponds to the inlet, the inlet is connected to the outlet, if it is water-cooled, The water outlet corresponds to the water return port, the water inlet corresponds to the water outlet, and the liquid discharge port (used when the heat medium is replaced) corresponds to the waste liquid collection and collection port.

In the selection of the pipeline, if the use of improper / damaged hoses and / or hose joints, it will lead to personnel injury, it is recommended that the metal insulation hose temperature range -60 ~ 250 ° C; pressure ≤ 2.5 bar.

Condensate adsorption recovery vocs When you carefully configure the metal insulation hose and other pipelines, please refer to their pressure and overpressure capabilities, caliber, and temperature range. At this time, it is necessary to consider the head pressure of the circulating pump inside the equipment. It is recommended that the condensing adsorption recovery vocs should select a pipeline of good quality and sufficient volume such as seamless steel pipe.

When selecting insulation materials, the temperature range of condensing adsorption recovery vocs should be considered first. It is necessary to select the flame retardant material. The temperature range of the insulation material should include the temperature range of the equipment, and there is a margin greater than 30 °C. When the user ignores this problem, There is a possibility of fire. There is also a sufficient amount of insulation material package for condensing adsorption recovery vocs, otherwise the equipment control will not achieve the expected results.

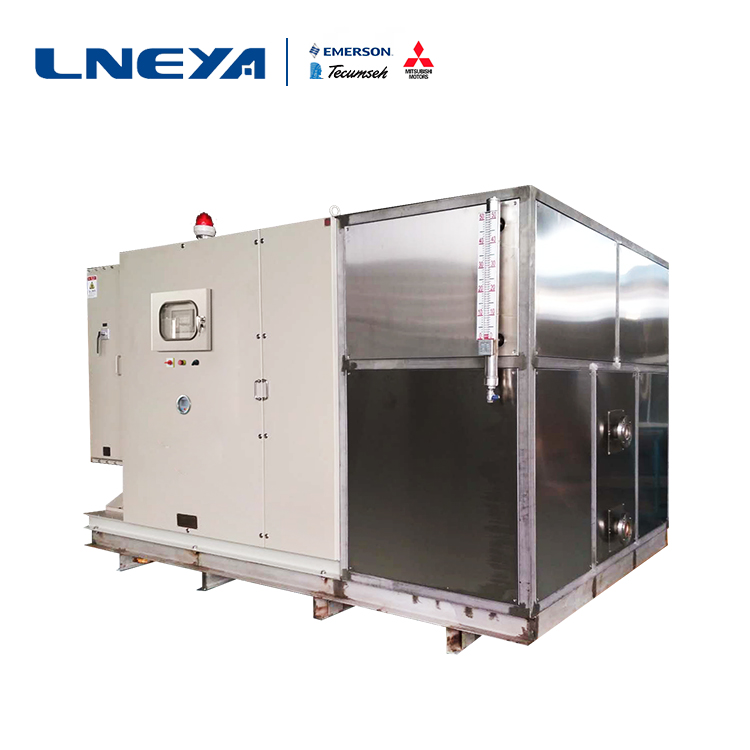

Each component of the condensing adsorption recovery vocs device is very important for its performance. Therefore, it is recommended that the user select the specific parameter configuration and then make a decision when selecting the condensing adsorption recovery vocs.

Raccomandazioni correlate

-

Liquid Cooled Battery Pack BMS Test Cooling Water Circulator

1906As the temperature gradually increases, the use of the cooling water circulator for the BMS test of the liquid-cooled battery pack also gradually peaks. The rated power of the cooling water circulator for BMS testing of liquid-cooled battery packs...

Visualizza dettagli -

Come verificare l'effetto refrigerante dei frigoriferi industriali?

1495For the user, how to check the cooling effect of the industrial refrigerator is an important part. LNEYA adopts a single-machine self-cascading refrigeration system. The environmentally friendly refrigerant and refrigeration effect users have a de...

Visualizza dettagli -

Pharmaceutical WFI system low-temperature cooling water circulator/chiller

1391The WFI (Water for Injection) system in the pharmaceutical industry is a highly purified water system that provides sterile water that meets strict quality standards for drug production and formulations (such as injections). ...

Visualizza dettagli -

Selection of heat transfer oil for the refrigeration and heating system of the reactor

1791In the chemical industry, the reactor is a commonly used container, and temperature control is the main quantity to be controlled. The heating and refrigeration cycle equipment of the reactor is an important factor to ensure product quality. The r...

Visualizza dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore