Why Is Temperature Uniformity Important for Testing Chambers

When you run a thermal test, the chamber must be fair to every sample. This article explains why temperature uniformity is an important characteristic for Camere di prova.

What is a testing chamber?

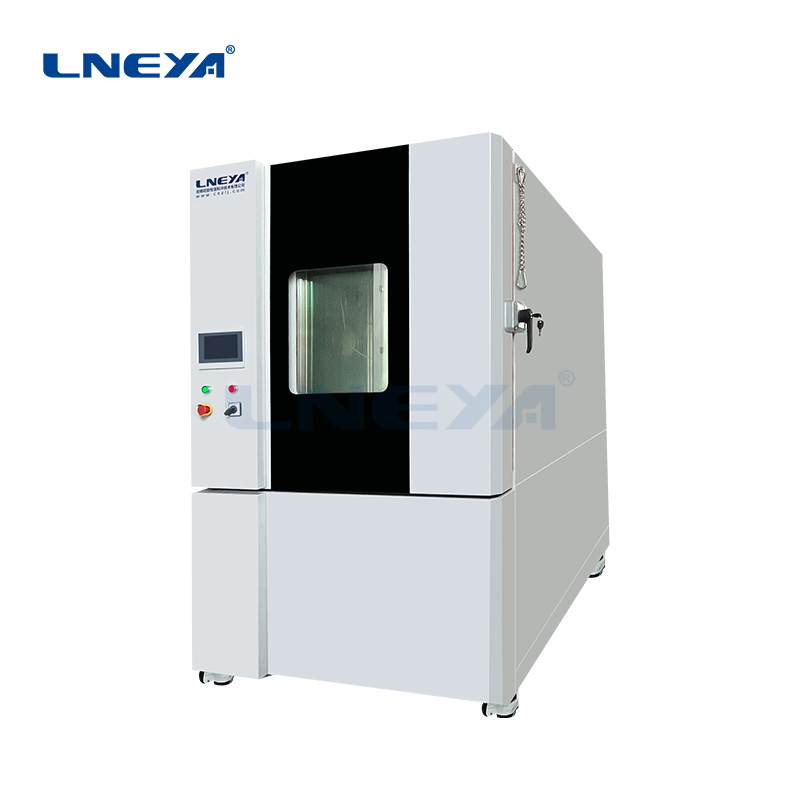

A test chamber is a device that simulates the environmental conditions, such as temperature, humidity, and pressure, that a material may encounter. Depending on their function, test chambers are categorized into various types, such as temperature chambers, temperature and humidity chambers, altitude chambers, and salt spray chambers.

It helps R&D personnel understand the performance of materials in real environments before mass production, allowing them to optimize their products. This is crucial for ensuring product quality, ensuring user safety, and maintaining the supplier’s brand image.

Therefore, test chambers are indispensable equipment in numerous industries, including semiconductors, automotive, pharmaceuticals, and aerospace.

What is temperature uniformity?

Temperature uniformity means how even the temperature is across the whole chamber volume. It is measured as the difference between the hottest probe and the coldest probe at steady state. Engineers usually run a probe grid and log readings after the chamber has stabilized.

Common practice uses nine to twenty one probe locations. For many standard tests labs aim for a spread under one degree Celsius at mid range setpoints. At extreme low or high setpoints the acceptable spread can increase.

The key is that uniformity is a measurable number. You can improve it by changing airflow, sensor placement, or load arrangement. You can also control it by tuning fan speed and by adding simple baffles.

Why is temperature uniformity important for testing chambers?

Uniform temperature is the basis of meaningful testing. When uniformity is poor, data reflects chamber faults more than product behavior. Below are the main reasons to control uniformity.

Reliable and Reproducible Results

When every point in the chamber sees the same temperature, variation from one sample to another drops. Repeatability depends on keeping test runs consistent.

Accurate Simulation of Real World Conditions

Even heat distribution helps represent field conditions accurately. Tests that match reality give useful design data. A chamber that mimics actual operating temperature must not introduce artificial gradients.

Compliance with International Standards

Many standards state probe layout, stabilization time and maximum spread. You must document your method. Calibrate sensors on a traceable schedule. Keep records of uniformity tests and the instrument certificates. Auditors check the log and the test reports. If you follow the listed procedures the test data stands up to external review.

Prevention of Testing or Production Failures

Non uniform chambers mask real issues and create false positives. Uniformity reduces both errors. If parts see unequal temperatures you cannot tell if failure results from product weakness or from chamber faults.

Consistent Product Quality

Even thermal treatment yields consistent end properties across a batch. Uniformity supports process control. Processes that rely on heat for curing or bonding depend on even exposure.

Reduced Rework and Waste

When uniformity is controlled, fewer samples fall outside specification. That reduces repeat testing and reprocessing.

Conclusione

When uniformity is under control your tests become repeatable and your process control becomes reliable. LNEYA provides various test chambers with temperature uniformity less than 1°C and fluctuation less than 0.5°C. If you need more precise equipment, we can also customize it for you according to your application

- Chiller Components and Refrigeration Fundamentals Guides

- Chiller Types and Selection Guides

- How Does a Peltier Cooler Work

- Peltier Chiller vs. Compressor Chiller

- What Is a Peltier Chiller

- OEM vs Aftermarket Chiller Spare Parts

- Chiller Surge

- Chiller Cooling Capacity Units

- Dicembre 2025

- Novembre 2025

- Ottobre 2025

- Settembre 2025

- Agosto 2025

- Luglio 2025

- Giugno 2025

- Maggio 2025

- Marzo 2025

- Febbraio 2025

- Gennaio 2025

- Dicembre 2024

- Novembre 2024

- Ottobre 2024

- Settembre 2024

- Agosto 2024

- Luglio 2024

- Giugno 2024

- Maggio 2024

- Aprile 2024

- Marzo 2024

- Febbraio 2024

- Settembre 2023

- Luglio 2023

- Giugno 2023

- Maggio 2023

- Gennaio 2023

refrigeratore raffreddato ad aria refrigeratore Chiller Maintenance refrigeratori Congelatore a freddo refrigeratore di raffreddamento sistema di controllo dinamico della temperatura chiller ad alta efficienza energetica circolatore di riscaldamento refrigeratore industriale refrigeratori industriali raffreddamento industriale congelatore industriale frigorifero industriale reattore a camicia refrigeratore da laboratorio refrigeratore a bassa temperatura notizie refrigeratore di processo Prozesskühlung raffreddamento del reattore riscaldamento del reattore raffreddamento circolatore refrigerato refrigeratore a vite refrigeratore per semiconduttori refrigeratore di prova per semiconduttori sundi tcu controllo della temperatura camera di prova termostato refrigeratore a bassissima temperatura refrigeratore di prova per veicoli refrigeratore d'acqua refrigeratore raffreddato ad acqua

Chiller correlati

CONTATTO

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

Hai una domanda o hai bisogno di un preventivo? Compila il modulo qui sotto e il nostro team ti risponderà entro 24 ore.

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore