Perché le macchine CNC hanno bisogno di chiller industriali

Che cos'è una macchina CNC?

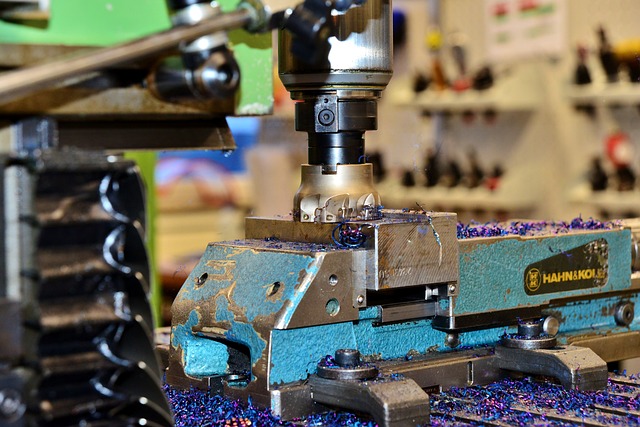

CNC (Controllo Numerico Computerizzato) è una macchina automatizzata per la lavorazione dei metalli che controlla gli utensili tramite computer. Controlla il percorso di movimento, la velocità, la velocità di avanzamento e la sequenza di lavorazione degli utensili tramite linguaggi di programmazione e può eseguire taglio di precisione, foratura, incisione e altre operazioni su materiali come metalli, plastica e legno. Le macchine CNC possono controllare l'errore di lavorazione a livello micrometrico e possono lavorare diverse parti ad alta precisione con strutture complesse. Dopo aver impostato il programma, la macchina può operare automaticamente 24 ore al giorno, indipendentemente dalla competenza dell'operatore, garantendo la coerenza dei lotti di prodotto.

Perché le macchine CNC si surriscaldano?

La lavorazione CNC causa un rapido accumulo di calore durante l'operazione. Le principali ragioni sono le seguenti:

Rotazione del mandrino

Il mandrino di una macchina CNC è il componente centrale che fa ruotare lo strumento. Quando si lavora il metallo, solitamente funziona a una velocità di diverse migliaia o anche decine di migliaia di giri al minuto. All'interno del mandrino ci sono i cuscinetti e quando i cuscinetti ruotano ad alta velocità, si genera attrito e calore tra i cuscinetti e la carcassa. Quando la temperatura del mandrino aumenta, esso si espande, influenzando la precisione della lavorazione. La maggior parte dei laboratori di produzione utilizza raffreddatori per olio del mandrino per raffreddare il mandrino e sopprimere l'espansione termica.

Generazione di calore per attrito

I centri di lavorazione CNC elaborano i materiali attraverso il taglio, il che genera calore a causa dell'attrito tra lo strumento e il materiale. Il calore da attrito tra i due è la principale fonte di calore. Specialmente quando si lavorano metalli duri come l'acciaio inox e le leghe di titanio, l'attrito tra lo strumento e il materiale è più intenso. Quando l'attrito è concentrato sulla punta dello strumento e in un punto specifico del materiale, la temperatura locale può raggiungere centinaia o addirittura migliaia di gradi Celsius. Il calore si trasferisce rapidamente dal punto di contatto al manico dello strumento, allo spindolo e ad altre parti del pezzo da lavorare.

Riscaldamento del motore e del driver

Gli utensili da fresatura CNC si basano su più motori servo per controllare il movimento di ciascun asse X, Y e Z. Quando il motore è in funzione, consuma energia elettrica e parte di questa energia si trasforma in energia termica. La conversione del calore è più evidente quando il motore viene avviato e fermato frequentemente e quando funziona ad alta velocità. Anche il driver del motore si riscalderà, e la temperatura può superare i 60°C o addirittura salire ancora di più dopo un lungo periodo di funzionamento. L'accumulo di calore può causare guasti elettrici.

Riscaldamento del sistema idraulico

Alcuni grandi utensili CNC e centri di lavorazione con sistemi automatici di cambio utensili utilizzano sistemi idraulici per controllare funzioni come i magazzini degli utensili, il cambio utensili, il serraggio e il rilascio degli utensili. Dopo che l'olio idraulico viene compresso nella pompa, si riscalda rapidamente. I componenti idraulici come gli attuatori, le valvole e i cilindri sono soggetti a usura, perdite o inceppamenti a causa delle alte temperature. Dotare il sistema idraulico di un raffreddatore per olio dedicato può mantenere la temperatura dell'olio all'interno del range appropriato.

Come aiuta un refrigeratore CNC nella produzione?

Migliorare la precisione di lavorazione

Il mandrino CNC si riscalda durante la rotazione ad alta velocità. La temperatura instabile provoca cambiamenti ripetuti nel volume del mandrino, causando errori nelle dimensioni di lavorazione. Se l'utensile non dissipa il calore in tempo durante la lavorazione, si accelera la passivazione e la bruciatura, influenzando la qualità della superficie del prodotto. Alcuni materiali sono sensibili alle variazioni di temperatura e possono accumulare calore durante il processo di taglio, causando deformazioni termiche e riducendo la precisione del prodotto finito. Il chiller può fornire raffreddamento a temperatura costante per il mandrino, l'utensile e il motore per migliorare la precisione della lavorazione.

Migliorare l'efficienza produttiva

Il sistema CNC dispone di un dispositivo di protezione integrato che forza lo spegnimento a temperature elevate. Dopo che la temperatura del sistema aumenta, il sistema rallenta automaticamente per ridurre il calore. Alcuni laboratori utilizzano lo spegnimento manuale per attendere il raffreddamento naturale della macchina. In entrambi i casi, il tempo di produzione viene sprecato. Il chiller fornisce raffreddamento continuo 7×24 ore per aiutare la linea di produzione a funzionare stabilmente a lungo e migliorare l'efficienza produttiva.

Prolungare la durata del servizio

L'alta temperatura può rendere l'olio lubrificante più fluido o addirittura carbonizzato, il che può causare l'usura a secco o il bloccaggio dei cuscinetti del mandrino. Può anche accelerare l'invecchiamento dell'isolamento, provocando guasti al servomotore o persino danni. Inoltre, l'aumento della temperatura dell'olio idraulico può causare l'invecchiamento delle guarnizioni, influenzando il funzionamento stabile della macchina. Componenti elettronici come inverter, PLC e schede circuitali sono soggetti a malfunzionamenti, errori o bruciature ad alte temperature. Il chiller può rimuovere il calore generato da queste parti in tempo, ritardare l'invecchiamento dei componenti e ridurre i costi di manutenzione dell'apparecchiatura.

Miglior sistema di raffreddamento CNC, miglior centro di lavorazione CNC

Le prestazioni stabili dei chiller CNC possono garantire una buona protezione della qualità del prodotto e dell'efficienza produttiva. LNEYA ha 15 anni di esperienza nella ricerca, sviluppo e produzione di apparecchiature per il controllo della temperatura ed è un produttore di chiller affidabile in Cina. Forniamo sistemi di chiller standard e servizi di chiller personalizzati con varie prestazioni. Puoi comunicarci qualsiasi tua esigenza e gli esperti di chiller ti aiuteranno a scegliere il sistema di controllo della temperatura CNC più adatto.

Raffreddatori correlati

CONTATTO

TEL:TELEMATICO

EMAIL: EMAIL: EMAIL: EMAIL: EMAIL: EMAIL: EMAIL

WeChat e WhatsApp:

Wechat QR

Hai una domanda o hai bisogno di un preventivo? Compila il modulo qui sotto e il nostro team ti risponderà entro 24 ore.

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore