Come migliorare l'efficienza dei refrigeratori? Formula di efficienza del refrigeratore inclusa

Still Frustrated by Low Chiller Efficiency? If your chiller isn’t performing as efficiently as you’d like, you’re not alone. This blog post dives into practical strategies for improving your chiller’s performance. Keep reading to discover smart, effective solutions that can boost efficiency and reduce operating costs.

Understanding Chiller Efficiency in 2025: What’s Changed?

Con il rapido progresso dell'industrializzazione, le aziende di vari settori sono alla continua ricerca di una maggiore efficienza produttiva e di una qualità superiore dei prodotti per rimanere competitive sul mercato. In questo contesto, i refrigeratori sono diventati sempre più importanti come apparecchiature di supporto critiche nei moderni processi industriali.

Le aspettative per le prestazioni dei refrigeratori sono aumentate in modo significativo. Oggi le aziende non solo hanno bisogno di refrigeratori per soddisfare le esigenze di raffreddamento di base, ma richiedono anche una maggiore stabilità e una migliore efficienza energetica. L'efficienza dei refrigeratori è diventata uno dei parametri fondamentali per la valutazione delle prestazioni complessive. È un fattore chiave per determinare se l'apparecchiatura può fornire un valore significativo nelle applicazioni reali.

Da un punto di vista sia tecnico che economico, il funzionamento efficiente dei refrigeratori ha un impatto diretto sui costi di produzione e sulla competitività complessiva. Di conseguenza, il miglioramento dell'efficienza dei refrigeratori è emerso come una delle principali aree di interesse del settore.

Il Formula di efficienza del refrigeratore Spiegato

Lo standard efficienza del refrigeratore formula è:

Efficienza del refrigeratore (kW/ton) = Potenza assorbita (kW) / Potenza frigorifera (tonnellate)

Più basso è il kW/ton, più efficiente è il refrigeratore.

7 modi per migliorare l'efficienza del vostro refrigeratore

I seguenti suggerimenti possono aiutarvi a migliorare l'efficienza del refrigeratore:

Monitoraggio e ottimizzazione delle condizioni operative

Prima di mettere in funzione un refrigeratore, è essenziale verificare che tutti i parametri del sistema rientrino negli intervalli appropriati.

La carica di refrigerante deve essere regolata con precisione in base alle condizioni operative specifiche per rimanere entro i limiti raccomandati. Sia la sovracarica che la sottocarica possono influire negativamente sulle prestazioni del refrigeratore. Inoltre, è consigliabile dare priorità all'uso di refrigeranti ecologici con un basso potenziale di riscaldamento globale (GWP).

Questi non solo riducono l'impatto ambientale, ma aiutano anche a rispettare standard normativi sempre più severi.

Il controllo del flusso di acqua refrigerata è un aspetto fondamentale per ottimizzare le prestazioni del sistema. Durante il funzionamento effettivo, la portata deve rispettare le specifiche di progetto per evitare sprechi di energia o potenziali danni al refrigeratore a causa di una portata insufficiente o eccessiva. L'installazione di dispositivi intelligenti di controllo del flusso può aiutare a monitorare e regolare continuamente il flusso in tempo reale, consentendo una gestione più precisa del sistema.

In generale, più bassa è la temperatura dell'acqua di raffreddamento, maggiore è l'efficienza del refrigeratore. Tuttavia, temperature troppo basse possono comportare un inutile consumo di energia. Pertanto, è importante trovare un setpoint equilibrato. Ottimizzando le impostazioni della temperatura dell'acqua di raffreddamento, è possibile migliorare sia le prestazioni di raffreddamento che i costi operativi.

Mantenere pulite le superfici di scambio termico

Dopo lunghi periodi di funzionamento continuo, i refrigeratori spesso accumulano incrostazioni, sporco e altre impurità sulle superfici dei tubi del condensatore e dell'evaporatore. Se non vengono puliti regolarmente, questi depositi si accumulano nel tempo, riducendo significativamente l'efficienza dello scambio termico. Di conseguenza, le prestazioni complessive del refrigeratore diminuiranno, rendendo difficile soddisfare le richieste di raffreddamento previste. Inoltre, il funzionamento in queste condizioni non ottimali può portare a una maggiore usura dei componenti interni, riducendo in ultima analisi la durata dell'apparecchiatura.

In circolatore refrigerato Nei sistemi di raffreddamento, l'acqua del rubinetto è comunemente utilizzata come fonte primaria di acqua di raffreddamento. Per garantire il corretto funzionamento del sistema e prolungare la durata di vita delle apparecchiature, è necessario prestare molta attenzione al trattamento dell'acqua. L'acqua del rubinetto, infatti, può contenere diverse impurità e minerali. Se non viene trattata adeguatamente prima di entrare nel sistema di circolazione, può causare problemi come l'ostruzione dei tubi, la corrosione delle apparecchiature e la riduzione dell'efficienza dello scambio termico.

Ad esempio, utilizzando metodi di filtrazione, addolcimento o trattamento chimico, è possibile ridurre la concentrazione di solidi sospesi, ioni di calcio e magnesio e altre sostanze nocive. Questo aiuta a prevenire l'accumulo di calcare e la formazione di sedimenti, garantendo un funzionamento efficiente e affidabile del sistema di refrigerazione.

Operare a carico parziale in modo efficiente

Nel funzionamento reale, raramente i refrigeratori funzionano a pieno carico in modo continuo. Nella maggior parte dei casi, il sistema funziona al di sotto della sua capacità massima, il che può portare a una riduzione dell'efficienza energetica. Per affrontare questo scenario comune e migliorare le prestazioni energetiche complessive, è consigliabile dotare i componenti chiave del refrigeratore, come il compressore, la pompa dell'acqua e il ventilatore, di azionamenti a frequenza variabile (VFD). Ciò consente alle apparecchiature di regolare dinamicamente la velocità di funzionamento e la potenza erogata in base alla domanda in tempo reale, ottenendo prestazioni più efficienti dal punto di vista energetico ed economico.

Implementare controlli intelligenti e automazione

Se il vostro attuale refrigeratore non dispone di funzionalità di controllo intelligenti, prendete in considerazione la possibilità di integrarlo in un sistema di gestione degli edifici (BMS) o in una piattaforma di controllo centralizzata. Questa integrazione consente di automatizzare le operazioni di avvio e arresto e di regolare con precisione il carico, migliorando l'efficienza operativa e riducendo il consumo energetico. Inoltre, i problemi di rumorosità associati al funzionamento del refrigeratore possono spesso essere attenuati ottimizzando il sistema di controllo.

Ad esempio, già nel 2021, LNEYA refrigeratori ha adottato il sistema di automazione PLM+UG+AD di Siemens per migliorare le prestazioni e il controllo.

In prospettiva, si raccomanda di introdurre, a partire dal 2025, sistemi di manutenzione predittiva basati sull'intelligenza artificiale. Questi sistemi sfruttano algoritmi avanzati e analisi dei dati per monitorare i principali parametri operativi in tempo reale e utilizzare i dati storici e le tendenze per prevedere potenziali guasti, consentendo una manutenzione proattiva e riducendo al minimo i tempi di fermo.

Misurare, valutare e migliorare

Durante il funzionamento del refrigeratore, i sistemi di monitoraggio avanzati possono essere utilizzati per tracciare e registrare in tempo reale i principali indicatori di prestazione, come i chilowatt per tonnellata di refrigerazione (kW/RT), il coefficiente di prestazione (COP) e il consumo energetico complessivo. La raccolta di questi dati fornisce una visione completa dello stato operativo attuale del sistema. Confrontando i dati in tempo reale con le prestazioni storiche, è possibile valutare con maggiore precisione se l'efficienza del refrigeratore sta diminuendo.

Inoltre, si consiglia di condurre regolarmente audit energetici completi. Questi audit non solo valutano il consumo energetico totale del refrigeratore, ma aiutano anche a identificare le opportunità di risparmio energetico nascoste nelle operazioni quotidiane.

Eseguire la messa a punto stagionale delle prestazioni

Dopo un periodo di funzionamento, i refrigeratori richiedono un'ispezione e una manutenzione regolari. A tal fine, è possibile contattare il produttore del refrigeratore per eseguire la messa a punto stagionale e garantire le prestazioni ottimali del sistema.

Il personale tecnico dei produttori di refrigeratori effettua periodicamente aggiornamenti e ottimizzazioni delle prestazioni. Quando sono disponibili nuove versioni del sistema, vi informeranno per aiutarvi a far funzionare al meglio la vostra apparecchiatura. È una buona idea tenersi informati sugli aggiornamenti e sugli sviluppi del produttore di refrigeratori.

Adeguamento o aggiornamento dove necessario

I refrigeratori più vecchi hanno spesso un'efficienza ridotta e potrebbero non essere più in grado di soddisfare le esigenze di raffreddamento delle moderne applicazioni industriali. Per migliorare le prestazioni, si potrebbe considerare l'ipotesi di un retrofit del sistema con azionamenti a frequenza variabile (VFD), motori ad alta efficienza o compressori a velocità variabile.

Se il ritorno sull'investimento è favorevole, si consiglia di sostituire le unità obsolete con un refrigeratore ad alta efficienza ed ecologico, come quelli offerti da LNEYA—for better long-term performance and sustainability.

Riflessioni finali: Sfruttate al massimo il vostro refrigeratore

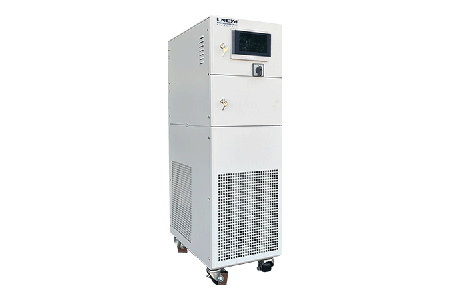

LNEYA è specializzata nel controllo termico a bassa temperatura da oltre 15 anni. Guidata da un impegno verso i principi della qualità e dell'attenzione al cliente, LNEYA si dedica a fornire soluzioni di sistema e servizi competitivi che creino costantemente un maggiore valore per i clienti.

Choosing LNEYA means choosing a more efficient chiller—and a smarter path to performance and reliability.

Refrigeratori consigliati

LT 10℃~30℃

macchina refrigerante

capacità di raffreddamento 3kW~14kW

flusso della pompa di circolazione 30L/min 1,6bar~50L/min 2bar

LT -25℃~30℃

circolatori di raffreddamento

capacità di raffreddamento 1kW~5kW

Portata della pompa di circolazione 30L/min 1,6bar

temperature accuracy ±0.5℃

LT -45℃~30℃

refrigeratori di precisione

capacità di raffreddamento 0,7kW~4,8kW

Portata della pompa di circolazione 30L/min 1,6bar

temperature accuracy ±0.5℃

LT -60℃~-30℃

circolatori refrigerati

capacità di raffreddamento 0,7kW~4,8kW

Portata della pompa di circolazione 30L/min 1,6bar

temperature accuracy ±0.5℃

LT -80℃~-40℃

refrigeratori a ciclo chiuso

capacità di raffreddamento 0,4kW~2,5kW

Portata della pompa di circolazione 30L/min 1,6bar

temperature accuracy ±0.5℃

LT-800 -18~30℃

mini refrigeratore

capacità di raffreddamento 0,35kW~0,9kW

Flusso della pompa di circolazione 10L/min 0,6bar

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore