camera di prova per batterie

GD -40℃~+100℃

Viene applicata principalmente nel campo delle batterie a nuova energia. La camera di prova per batterie fornisce un ambiente di test con controllo della temperatura da alta a bassa, oltre al controllo del flusso e della pressione per i campioni di batterie a nuova energia.

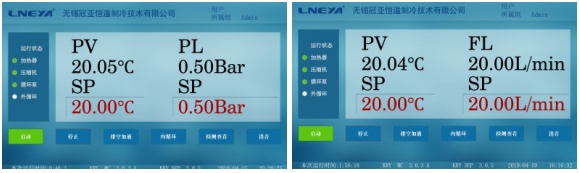

LNEYA’s battery test chamber adopts a double-layer design for high and low temperature control. Currently,The temperature control range of antifreeze and chamber is -40℃~+100℃. The environmental chamber for battery testing can provide a temperature range of -45℃~+100℃. The flow rate control range of antifreeze is 1L/min~25L/min.C

| Modello | GD-9000-2-B1-KRYCH-4A15W | GD-9000-2-B1-KRYCH-475W | GD-9000-2-B1-KRYCH-4A10W | GD-1000-B1-KRYCH-475 | |||||

| Controllo del flusso di antigelo | 1L/min~40L/min | 1L/min~25L/min | 1L/min~25L/min | 1L/min~10L/min | |||||

| ±0.2L/min | ±0.2L/min | ±0.2L/min | ±0.2L/min | ||||||

| Pressione dell'antigelo | Misurazione e visualizzazione della pressione in ingresso e in uscita, nonché della pressione visualizzata sul touch screen | ||||||||

| Potenza di riscaldamento | 15kW | 14kW | 7,5kW | 14kW | 10kW | 14kW | 7,5kW | 6kW | |

| Capacità di raffreddamento antigelo | 135℃ | 15kW | 7,5kW | 10KW | 7,5kW | ||||

| 20°℃ | 15kW | 7,5kW | 10KW | 7,5kW | |||||

| 0℃ | 15kW | 7,5kW | 10KW | 7,5kW | |||||

| -20℃ | 10kW | 4,5kW | 6KW | 4,5kW | |||||

| -35℃ | 4kW | 1,8kW | 2,5KW | 1,8kW | |||||

| Precisione del controllo della temperatura dell'antigelo | ±0.1℃ | ||||||||

| Uniformità della temperatura | ≤±1℃(unloaded) | ||||||||

| Cooling water 20 ℃ | 25m³/H | 20m³/H | 20m³/H | 7m³/H | |||||

CAN/TCP/RS485

Pompa a trasmissione magnetica

380V 50HZ

Vantaggi di camera di prova per batterie

Materiale del tubo

Il materiale del tubo dell’unità industriale chiller-riscaldatore WTD è SUS304, che offre maggiore resistenza alla corrosione atmosferica, all’ossidazione e al calore, garantendo al tuo chiller una vita più lunga e costi di manutenzione inferiori.

Spazio a pavimento

Il chiller-riscaldatore ricircolante WTD utilizza uno scambiatore di calore a piastre con struttura compatta e ingombro ridotto, adatto all’uso in luoghi con spazio limitato. La parte inferiore è dotata di 4 ruote, che consentono di spostarlo facilmente secondo le necessità.

Accessori principali

Gli accessori del chiller-riscaldatore industriale WTD sono fondamentalmente di marchi internazionali rinomati. Ad esempio, il compressore utilizza Secop, Emerson Copeland e il francese Tecumseh; il filtro a secco utilizza Danfoss; il contattore/interruttore automatico utilizza Schneider.

La pompa a frequenza variabile può regolare la pressione idraulica di circolazione e la portata per ottenere un controllo di alta precisione della gamma totale da 5% a 100%.

(La pressione di uscita e la portata del fluido circolante possono essere impostate sul pannello di comando. Anche in diverse condizioni di tubazioni del cliente, senza la regolazione delle tubazioni di bypass, la pressione di uscita impostata può essere controllata automaticamente dalla pompa a frequenza variabile. Ciò consente di ridurre il consumo energetico della pompa.)

Tutte le camere di prova ambientali modello

GD -40℃~100℃

camera di prova per batterie

Capacità di raffreddamento 1,8kW~15kW

Potenza di riscaldamento 6KW~15KW

Temperature uniformity ±1℃

GD -80℃~150℃

camera di prova climatica

Heating rate (+20~+150℃)A:5℃/min

Cooling rate Carrying idler (+20~-40℃)5℃/min

GD -40℃~180℃

camera di shock termico

Low temperature -40~0℃

High temperature +60~+150℃

Temperature fluctuation ≤1℃

You can trust our camera di prova per batterie factory

In qualità di leader nel settore della refrigerazione, LNEYA attribuisce sempre grande importanza all'innovazione tecnologica. LNEYA possiede oltre 90 brevetti di invenzione e 20% degli oltre 400 dipendenti sono tecnici. Il processo di produzione adotta la piattaforma di progettazione PLM di Siemens per gestire in modo uniforme tutti i dati dell'intero ciclo di vita del prodotto, dalla progettazione, alla vendita, alla produzione, al post-vendita fino alla rottamazione, per massimizzare la tracciabilità della qualità del prodotto.

Servizio globale

Abbiamo servito più di 30.000 clienti.

Esportato in oltre 20 paesi.

Brevetti di certificazione

Ha ottenuto la certificazione CE, la certificazione SGS e la certificazione ISO.

Assistenza post-vendita

Fornire una formazione tecnica completa.

Con soluzioni 24/7.

Team professionale

Fondata nel 2010, con 15 anni di esperienza nel settore.

Il 20% dei dipendenti sono tecnici.

Controllo qualità

Ispezione visiva

Test di prestazione.

Test di sicurezza elettrica.

Mettetevi in contatto con i nostri esperti di camere di prova per batterie

Contatta LNEYA

Invia la tua richiesta e ti contatteremo entro 24 ore

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore