Why is there air in the reactor temperature control system?

The impurity gas in the reactor temperature control system is to increase the condensing pressure of the refrigeration system, thereby increasing the condensing temperature, increasing the exhaust temperature of the compressor, increasing the power consumption, reducing the cooling efficiency, and possibly the exhaust gas temperature is too high. The carbonization of the lubricating oil affects the lubrication effect, and in severe cases, the refrigeration compressor motor is burnt.

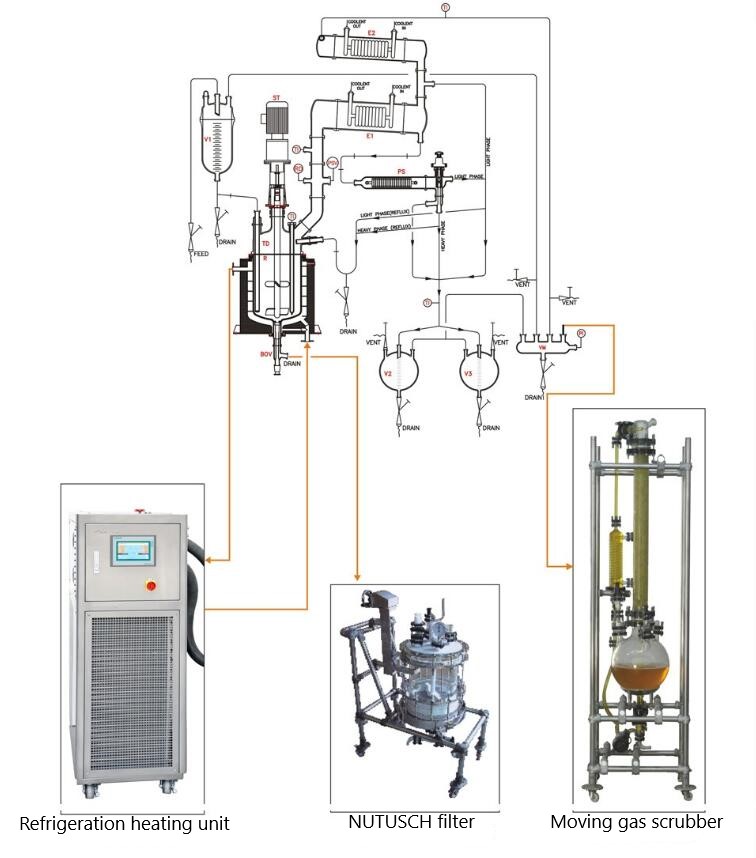

The gas generated in the reactor temperature control system may be leaking air. It may be when the refrigerant is filled or lubricated, the outside air is taken into the air, or the temperature of the reactor temperature control system is not tight enough to cause air to enter. Inside the system. In addition, gas is generated due to decomposition of the refrigerant oil, impure refrigerant, and corrosion of the metal material. Of course, Wuxi Guanya uses a fully enclosed circulation system on the reactor temperature control system to prevent this air from entering the reactor temperature control system.

In general, the gas in the reactor temperature control system is expressed in the reactor temperature control system compressor exhaust pressure and exhaust gas temperature rise, the pressure gauge pointer on the condenser (or reservoir) violently swings, the compressor The cylinder hair is hot, the condenser shell is very hot; the surface temperature of the evaporator temperature control system is unevenly frosted. When there is a large amount of gas in the reactor temperature control system, the ambient temperature cannot be lowered due to the decrease of the cooling capacity of the reactor. The machine runs for a long time, and even the high-pressure relay operates to stop the compressor.

If the reactor temperature control system has these gases, the pressure of the refrigeration system can be measured by a pressure gauge to compare with the saturation pressure at that ambient temperature. If the measured pressure is greater than the saturation pressure at ambient temperature, the system contains gas.

If the above-mentioned gases are found in the reactor temperature control system, it is necessary to eliminate these gases in time and solve the faults in time.

Raccomandazioni correlate

-

Istruzioni per la manutenzione del compressore delle apparecchiature per il trattamento dei gas di condensazione Vocs

955L'apparecchiatura per il trattamento di condensazione dei gas di scarico è un'apparecchiatura importante nel processo di trattamento dei gas di scarico. Tra questi, il compressore è uno dei componenti principali e le sue prestazioni influiscono sull'efficienza operativa dell'intero impianto di trattamento dei gas di...

Visualizza i dettagli -

Suitable Freezer Manufacturer

899For enterprise users, choosing a suitable freezer manufacturer is very important and must be carefully treated. Wuxi Guanya Refrigeration technology co., Ltd, as a professional freezer manufacturer, is committed to producing all kinds of low tempe...

Visualizza i dettagli -

Circolatore chiuso da laboratorio vasche di miscelazione smaltate sistema di refrigerazione e riscaldamento

835Closed laboratory enameled mixing tanks refrigeration and heating system

Visualizza i dettagli -

Main points of maintenance of LNEYA ultra-low temperature refrigeration circulator

1090Ultra-low temperature refrigeration circulators need to be maintained after a long period of operation, so what aspects should be paid attention to? Check and maintain the ultra-low temperature refrigeration circulator on time. It can find problem...

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore