Requisiti per l'installazione dei crio refrigeratori a glicole etilenico

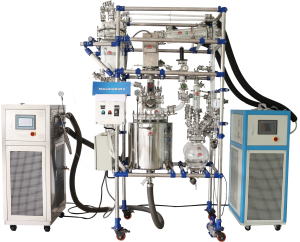

After the purchase of ethylene glycol cryo chillers with professional manufacturers Wuxi Guanya, installation requirements will be sent to the hands of users with the equipment. So, what needs to be paid attention to during the installation of ethylene glycol cryo chillers?

In summer, ethylene glycol cryo chiller is frequently used, and ethylene glycol cryo chiller is also needed by everyone. Therefore, during the installation of ethylene glycol cryo chillers, it needs to be installed on a smooth and tidy ground. Then, why should we choose a smooth ground when installing? Users who know about ethylene glycol cryo chiller may know that if the ethylene glycol chiller is inclined during installation, it may cause abnormal operation of refrigerant, cooling water or chilled water.

Ethylene glycol chillers make the compressor run more efficiently when running on a smooth surface. Because gravity is considered in the normal operation of each part of the compressor, the smooth ground can avoid the resistance of the liquid medium in the flow or gravity acceleration, so as to run the ethylene glycol cryo chiller more effectively.

Of course, the problem of noise is constantly troubling many users of ethylene glycol cryo chiller. In fact, the smooth ground can effectively reduce the vibration and noise during operation, because the smooth ground can reduce the vibration during operation, which is beneficial to the mute effect of ethylene glycol and enhance its service life.

If the ethylene glycol cryo chiller is running on uneven ground, due to the effect of gravity, each part in the ethylene glycol cryo chiller running on the basis of the vibration may confront a greater chance of loosening, peeling.

Raccomandazioni correlate

-

The use and characteristics of the SUNDI series of high and low temperature cooling circulators

1212The SUNDI series of high and low temperature cooling circulators are equipment for direct or auxiliary heating in the fields of biology, physics, chemical engineering, medical treatment, environmental protection, etc. Moreover, the temperature con...

Visualizza i dettagli -

Quali sono i componenti che migliorano le prestazioni dei refrigeratori industriali?

1043Industrial chillers are indispensable equipment in LNEYA production. With its normal operation, we will have better work efficiency and higher product quality. The refrigeration system of an industrial chiller is mainly composed of four core compo...

Visualizza i dettagli -

Product Features of Fluid Heat Transfer Temperature Control System

1007The fluid heat transfer temperature control system is the refrigeration and heating device of the matching reactor reactor in the pharmaceutical chemical industry. So, what are the characteristics of the fluid heat transfer temperature control sys...

Visualizza i dettagli -

Temperature control range and accuracy of high and low temperature tester

1019The temperature control accuracy of heat transfer oil medium of the high and low temperature tester used for component testing is plus or minus 0.5 ℃, which solves the problem of temperature control lag in electronic components. Main advantages of...

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore