Several Common Troubleshooting Methods for Ultra-low Temperature Freezer in Laboratories

Although the refrigeration system and control circuit of ultra low temperature freezer in laboratory are complex, the common faults are mainly circulating system and circuit part.

Following are several common faults of ultra-low temperature refrigerators and their troubleshooting methods:

1. After power supply is switched on, the air switch of the main power supply is automatically disconnected.

Elimination method: Check whether the compressor of refrigeration system is damaged or not, and replace the parts if damaged. After replacing the fittings, turn on the machine to check whether it is normal. The fault is usually caused by unstable power supply, because the * stage starts first, so the damage is usually in stage. In this case, as long as the delay regulated power supply is installed, the fault will not occur again.

2. Stop working before the temperature in the box reaches the set temperature.

Exclusion: Although the temperature in the box has not reached the set temperature, the panel display temperature has reached the set temperature. This is due to the damage of the thermistor which detects the temperature and the need to replace the parts. If there is no original accessories, a set of temperature control system can be re-installed to eliminate the failure.

3. Poor refrigeration effect may be refrigerant leakage

4. If the ultra-low temperature refrigerator does not start in winter, it may be that the thermostat regulation value is too small.

We are a ultra low temperature freezer manufacturer. Welcome to choose our products.

Raccomandazioni correlate

-

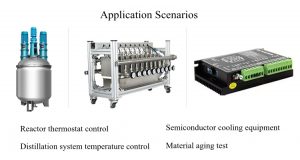

Temperature Control Soultion for Wafer Cleaning Solution in Semiconductor Industry

1192With the rapid development of semiconductor technology, the requirements for wafers are getting higher and higher, making clean wafer surfaces more and more important for the manufacturing of semiconductor devices. In the wafer manufacturing proce...

Visualizza i dettagli -

How to choose the accessory pump in the new energy vehicle battery test?

929New energy vehicle battery testing plays a more important role in the development of new energy vehicles. In the operation process, the pump is the key supporting equipment in the LNEYA test equipment, which is also concerned by people. So how to ...

Visualizza i dettagli -

New energy shaft cooling chiller

811New energy shaft cooling does not necessarily require industrial freezers, but is usually achieved using industrial chillers or cooling systems. Industrial freezers are mainly used for extremely low temperature freezing and processing, w...

Visualizza i dettagli -

Come risolvere il guasto del sistema di controllo automatico della temperatura del reattore?

1155Le prestazioni del sistema di controllo automatico della temperatura del reattore sono molto importanti. Una volta riscontrato un guasto che non può essere avviato, è necessario risolverlo il prima possibile, altrimenti la temperatura incontrollabile influirà sul reattore...

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore