The importance of temperature cycle control heating and cooling in the production of API

China has become the world’s largest supply market for APIs. Most of the APIs and intermediates required by foreign manufacturers are purchased in my country. The drug outsourcing process of most of its preparation products, the production process of APIs is much more complicated, the process is long, the pipelines are many, the operation is complicated, and most of the APIs are unstable, such as high environmental parameters such as temperature, humidity, and light. Raw materials are also flammable and explosive. Different from the preparation product process, most of the production process of APIs is a cross-fusion process of chemical and physical, such as product discoloration, extraction and adsorption.

In the pharmaceutical industry, the temperature control process runs through research to production. In order to obtain high-quality reaction products, the temperature control system must reliably control the process changes in the external reactor.

Pharmaceutical companies use a variety of continuous or mass production processes to produce their products. Depending on the final form of the product, use extrusion equipment, agitators, mixers or jacketed containers. Each of these steps requires heating, cooling, or both during the manufacturing process and due to the inherent chemical nature of the drug, they may be more sensitive to processing time and temperature exposure than many other consumer products.

Cooling heating system or temperature control of heating system is used for pharmaceutical processing, cooling/heating cycle control process. Because the temperature of the product is always consistent and accurate throughout the mixing operation, the pharmaceutical processing equipment has achieved uniform mixing to a large extent. Temperatures outside the established range usually have an adverse effect on the active pharmaceutical ingredient (API).

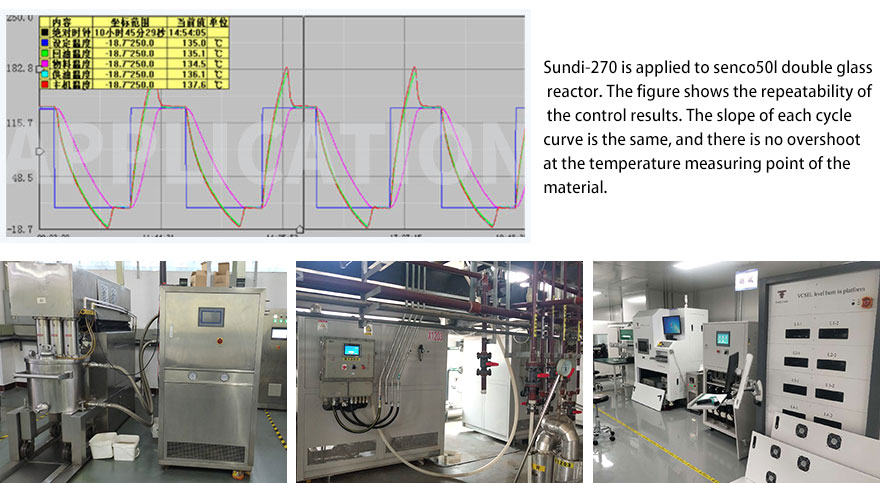

Lneya dynamic temperature control system is used for dynamic constant temperature control of cold and heat sources of various reactor reactors. The temperature range is -120 ℃ to 350 ℃, ultra-high temperature cooling technology can be directly cooled from the high temperature of 300 ℃. High temperature heat medium will not evaporate at high temperature, continuous control can be achieved in the range of -80 ℃ to 190 ℃, using plate heat exchangers, tube heaters to increase heating and cooling rate. It is mainly used in conjunction with double-layer glass reactors and can provide heat and cold source circulation devices. It has a wide working range and is used in pharmaceutical, chemical, biochemical, biological and other industries. It also provides heat and cold sources for reactors and tanks. It is also available. Used for heating and cooling of other equipment.

Raccomandazioni correlate

-

Influence of Freezing Oil on New Energy Vehicle Drive Motor Test System

1174The hazard of the refrigerating oil in the new energy vehicle drive motor test system increases the condensation temperature and the condensing pressure; the condenser heat transfer deteriorates. Because the oil film produced by the oil entering t...

Visualizza i dettagli -

High and low temperature cycle machine compressor performance description

1191The importance of the performance of high and low temperature cycle machine compressors must be known to everyone, then LNEYA reminds users that it is necessary to understand the common sense of the performance of the compressor. The high-low temp...

Visualizza i dettagli -

How to deal with the installation of the hot and cold integrated control machine?

1192Since the thermocouple's thermal inertia causes the meter's indicated value to lag behind the measured temperature, this effect is particularly pronounced when performing rapid measurements. Therefore, thermocouples with thinner thermal electrodes...

Visualizza i dettagli -

What is the local overheating machine room water chiller?

1081What is the local overheating machine room water chiller?

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore