Troubleshoot the main points of failure of the high and low temperature cooling system

When the industrial high and low temperature cooling system is in use, what is the general reason if the temperature cannot drop down? How should we deal with such failures?

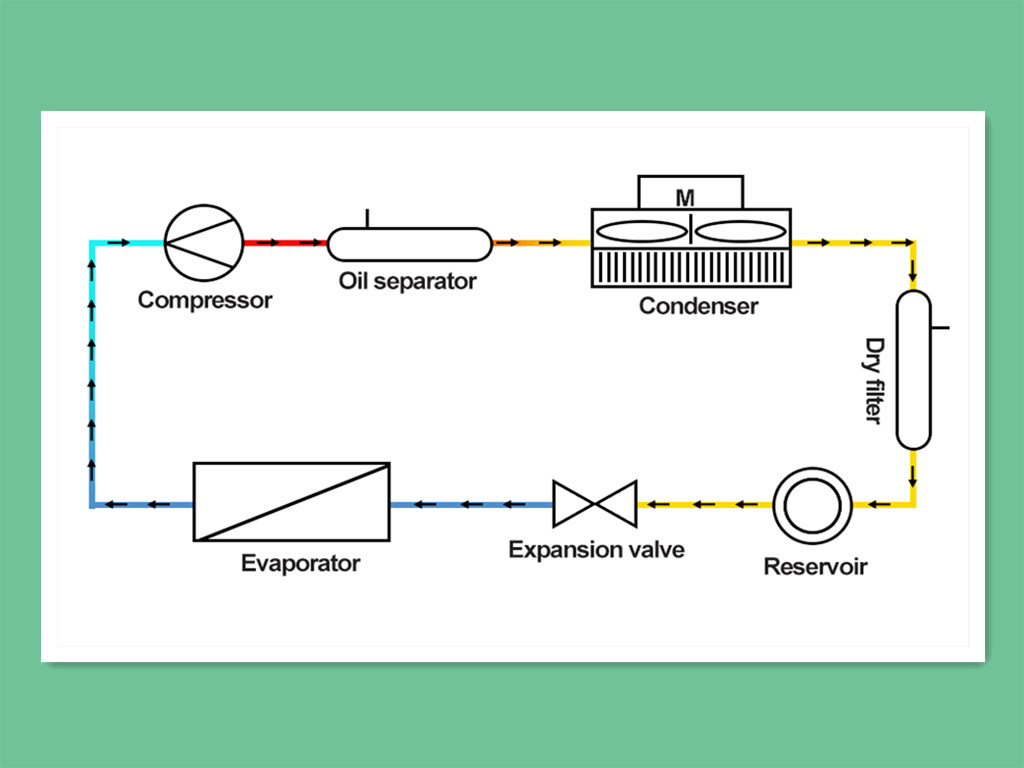

Let’s first analyze the principles and methods of industrial cooling. The circulating heat transfer medium is different. Generally, the high and low temperature cooling system industry mostly uses direct cooling, while indirect cooling is used, with plate heat exchangers or oil coolers installed inside. In other devices, the heat medium and cooling water source in the system exchange heat in the heat exchanger to reduce the temperature of the medium.

The temperature of the high and low temperature cooling system cannot be reduced. Generally, we conduct inspection and maintenance from the following aspects:

1. The cooling solenoid valve is damaged: it is necessary to check whether the solenoid valve coil can work normally, if it is damaged, it needs to be replaced; the panel does not output a cooling signal, carefully check the circuit or use the component replacement method to check.

2. Circuit failure: Check the circuit part of the system, the cooling water inlet or outlet pipeline is blocked: check whether the valve in the cooling water pipeline is fully opened, and ensure that the flow and pressure of the cooling water are sufficient, and the heating contactor is stuck, Always heating: observe the pull-in state of the contactor, and worsen damaged electrical parts.

In addition to troubleshooting the above two possible causes of failure, we also need to check whether the cooling plate is replaced or the cooling exchanger is blocked.

The advantage of using indirect cooling is that it has high temperature control accuracy and strong adaptability. It can be applied to the temperature control of high and low temperature cooling system industries. And because the heat transfer medium is cooled first, the cooling impact on the temperature control equipment is relatively small. Of course The disadvantage is that the cooling speed is relatively slow, and the price is more expensive than direct cooling.

Raccomandazioni correlate

-

How to install -60°C cryogenic chiller manufacturers equipment

1206-60℃ cryogenic chillermanufacturers are used in the refrigeration and chemical industry, so whatissues should be paid attention to during installation? LNEYA professionalmanufacturers tell you that you should install according to the instructio...

Visualizza i dettagli -

Controller function of industrial chiller

1362In the use of industrial water chiller, the controller is the key point, so, do you know the function of the chiller temperature controller? Today, we're going to talk about it! 1. The flow switch of the chiller is used as the control or interrupt...

Visualizza i dettagli -

Refrigeratore per bollitore di distillazione da 200 l

781Il refrigeratore per il bollitore di distillazione da 200 litri deve soddisfare due funzioni principali allo stesso tempo: una è quella di condensare il vapore di metanolo e l'altra è quella di raffreddare il materiale durante il processo di reazione. ...

Visualizza i dettagli -

Come risolvere la mancanza di capacità di raffreddamento del sistema del ciclo di raffreddamento dei semiconduttori?

1071Il sistema a ciclo di raffreddamento dei semiconduttori è un dispositivo per il raffreddamento della parte riscaldante del semiconduttore nelle apparecchiature di refrigerazione. Viene comunemente utilizzato per testare parti di circuiti integrati a semiconduttore, parti elettroniche di autoveicoli, componenti di fibre ottiche,...

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore