Cooling and heating of the reactor and the principle of use

Cooling and heating circulator thermostats are commonly used with glass reactors for biochemical instruments. They are widely used in modern fine chemicals, biopharmaceuticals, scientific research and experiment industries. They can be concentrated, distilled, Will stay, separate and purify the reaction. In the production process, whether it is a double-layer glass reactor or a single-layer glass reactor, the refrigeration heating temperature control system can generally complete high temperature, low temperature, and vacuum reaction experiments at the same time. Under constant temperature conditions, in a closed container, the refrigerating and heating circulator can be combined with a glass reactor to carry out stirring and reaction under normal or negative pressure, and can control the evaporation and reflux of the reaction solution.

One of the methods of obtaining high temperature is steam heating. When the cooling and heating temperature control system is matched with the glass reactor, the heating temperature is required to be below 100°C, and the glass reactor can be heated by steam. In this method, the equipment is heated with subatmospheric steam. When the temperature is required to be in the range of 100°C to 180°C, saturated steam can be used; when the temperature is required to be higher, high-pressure superheated steam can be used for heating.

Different manufacturers’ isolation reactor heating circulators are designed with different temperature ranges and media. It is necessary to select the appropriate media according to the available media of the equipment. Common media include water, oil, refrigerant, etc. The cooling process of the equipment is to use the refrigerant to absorb the excessive heat of the equipment and evaporate it to achieve the purpose of temperature difference.

The principle of temperature control of the matching reactor is indirect temperature control. The temperature is controlled by the heat transfer oil or other medium in the jacket of the reactor and the coil, and the temperature of the reactor wall is raised and lowered through the medium.

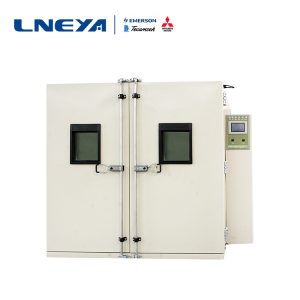

Our LNEYA heating circulator can set the working temperature and alarm temperature on the equipment digital display, press the heating option, after the indicator light is on, you can adjust its heating power through power selection; when using heat transfer oil, it is recommended to directly contact the equipment The manufacturer purchases the corresponding heat transfer oil. When using it, the heat transfer medium cannot contain water, otherwise it will cause equipment failure.

Raccomandazioni correlate

-

Descrizione del vantaggio del marchio della scatola di prova passo dopo passo

1229La scatola di prova walk-in è sviluppata e prodotta da LNEYA. È specializzata nella tecnologia di produzione farmaceutica e fornisce ai clienti vari modelli di marchi. Presenteremo quindi il prossimo test box di tipo "walk-in". Benvenuti a consultare e imparare.

Visualizza i dettagli -

Il sistema di refrigerazione di un refrigeratore criogenico

981Negli ultimi anni, i refrigeratori criogenici sono sempre più diffusi nel mercato industriale nazionale. Molte produzioni industriali hanno bisogno di un maggiore aiuto da parte dei refrigeratori criogenici per ottenere un ambiente ideale a bassa temperatura. Pertanto, i refrigeratori criogenici...

Visualizza i dettagli -

Product description for ultra-low temperature refrigeration

1028Technical parameters (low temperature cold storage project within 100 cubic meters) of Ultra-Low Temp Cold Storage 1. Medical cold storage temperature range(℃):Low-temperature storage library: -20°C to -50°C Preservation of plasma, biological ma...

Visualizza i dettagli -

Performance and installation points of LNEYA ultra-low temperature refrigerator

890LNEYA Ultra-Low Temp. Freezer is widely used in blood stations, hospitals, health, and epidemic prevention departments, research institutes, electronics industry, chemical medicine, biological engineering, laboratory, military industrial enterpris...

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore