How does the cooling and heating system achieve simultaneous temperature control?

Temperature control system The thermostat has heating and cooling functions, and can use the same medium for continuous temperature control from -120℃~320℃.

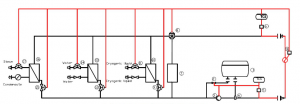

The heating and cooling system of cooling and heating system is mainly composed of four parts: heat exchanger, compressor, evaporator and condenser, and it is also one of the very key components of the whole high and low temperature integrated machine. The heat exchanger is mainly to transfer heat from the hot fluid to the cold fluid, the heat exchanger has a four-way valve, which can cool the heat exchanger. The condenser is part of the cooling system of the high and low temperature all-in-one machine, which converts gas or vapor into liquid, and can transfer the heat in the pipe to the nearby air. The evaporator is one of the very important components of refrigeration. The low-temperature condensate exchanges heat with the outside air through the evaporator, and evaporates to absorb heat. The evaporator is mainly composed of a heating chamber and an evaporation chamber. The heating chamber provides the heat needed to evaporate the liquid to promote boiling and evaporation of the liquid.

The cooling and heating system is suitable for equipment connected to reaction devices for refrigeration and heating reactions in the pharmaceutical and chemical industries. There are many production steps that require reliable temperature control as part of prototyping equipment. The working principle is to drive the heat transfer medium (usually water, ethanol, silicone oil, etc.) from the oil tank with built-in heater to the temperature control equipment through the pump, and then return to the oil tank from the temperature control equipment. The controller adjusts the temperature of the thermal fluid to adjust the temperature of the temperature control device according to the temperature of the thermal fluid measured by the temperature sensor or the internal temperature of the temperature control device. In recent years, there have been more and more applications in the chemical industry. After purchasing the high and low temperature cycle machine, it is necessary to carry out actual operation, but many users are not very familiar with its main operation. If the operation is not performed according to the requirements, it will not only affect the performance and life of the equipment, but may even be dangerous. Accidents happen.

Raccomandazioni correlate

-

Condivisione delle conoscenze sulla selezione e la manutenzione dei refrigeratori

1127I refrigeratori possono essere utilizzati in molti settori industriali, ma chi è il miglior produttore di refrigeratori a bassa temperatura tra i migliori produttori di refrigeratori? Lasciate che ve lo dica. Anche la scelta del modello e la manutenzione sono molto importanti. Quindi, vedete con me. 1. Gamma di...

Visualizza i dettagli -

Chemical synthesis process control system temperature control system TCU

1100Today, let's talk about our DCS integrated control system (temperature and other control of synthetic process). Scalability: the system is an open system, which provides standard TCP / P data communication interface protocol, interface software an...

Visualizza i dettagli -

Method for controlling shutdown of water cooled chiller of single reaction kettle

1270The reaction kettle water cooled chiller has a wide range of accessories and equipment. In actual use, it needs to be provided with regular rest time. In order to maintain the stable performance of the refrigerator during long-term operation, it i...

Visualizza i dettagli -

Apparecchiature di supporto del reattore dell'industria farmaceutica Termostato ad alta e bassa temperatura

910Il termostato ad alta e bassa temperatura è un dispositivo di controllo della temperatura utilizzato nell'industria farmaceutica per riscaldare il reattore per periodi di tempo diversi. È semplice e comodo da utilizzare e può migliorare rapidamente l'aumento della temperatura e la...

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore