Industrial Chiller Maintenance You Should Know

The Importance of Industrial Chiller

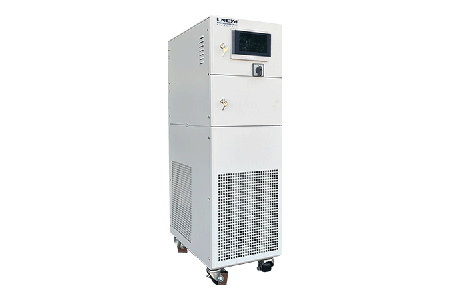

LNEYA’s industrial chillers are designed to protect equipment from damage through precise temperature control while boosting production efficiency and cooling performance. Our chillers are typically used in large-scale industrial applications, with a typical service life of 10 to 15 years.

Given the high upfront investment and long-term operation, the running and maintenance costs can be significant over time. That’s why proper maintenance and extending the lifespan of your industrial chiller is the most economical way to maximize your return on investment.

Industrial Chiller Maintenance Checklist

To help you avoid commonly overlooked maintenance issues during use, LNEYA has prepared a chiller maintenance schedule to ensure your chiller system operates reliably and efficiently:

- Ensure the chiller room is well-ventilated, dry, and clean

- Check whether chiller operating parameters are within safe operating ranges.

- After powering on, verify all system indicators are functioning properly

- Listen closely for any unusual noises during operation

- Check for refrigerant leaks or reduction in refrigerant levels

- Confirm cooling water temperature and pressure are within proper ranges

- Inspect the external casing and internal piping for signs of corrosion

- Examine key components — compressor, condenser, evaporator, and expansion valve — for abnormalities

- Ensure the lubrication system is smooth and functioning properly

- Check that the inlet and outlet ports are not blocked

Note:

- The protective settings of the chiller system are preset by the manufacturer; do not adjust them without guidance, as it may cause unexpected issues.

- Maintenance standards and methods vary by manufacturer and should be adapted to your specific system.

- Air-cooled and water-cooled chillers require different maintenance approaches.

Preparation Before Industrial Chiller Maintenance

Personnel Arrangement

Before beginning maintenance work, chiller operators must undergo chiller maintenance training and be educated on responsibility and safety awareness.

In general, common chiller problems should be handled jointly by trained operators and professional maintenance engineers.

For more complex problems, a report should be submitted. Department and unit leaders should then organize and assign personnel to carry out repairs in an orderly and efficient manner.

Material Preparation

It is essential to have necessary materials on hand in case of unexpected maintenance needs.

Wearing Parts: Valve springs, piston rings, packing materials, valve plate bushings, gaskets, piston pins, shaft seals, rubber sealing components, main bearings, connecting rod bolts, pistons, and cylinder sleeves.

Auxiliary Materials: Gauze, gasoline, kerosene, refrigeration oil, oil pans, fine sandpaper, lapping paper, oilstones, etc.

Note: Flammable materials such as gasoline and kerosene must be stored in a safe area away from open flames and high temperatures.

Tool Preparation

Standard Mechanical Tools: Lifting bolts, socket wrenches, adjustable wrenches, hacksaws, pliers, hammers, screwdrivers, pipe wrenches, etc.

Instruments & Measuring Tools: Feeler gauges, vernier calipers, outside micrometers, dial indicators, inside micrometers, calipers, and frame spirit levels

Tips of Industrial Chiller Maintenance

Regular Cleaning of the Condenser and Evaporator

As two of the four core components in the refrigeration system, the condenser (liquefaction) and evaporator (vaporization) play a critical role in cooling performance. To prevent frost blockage, dust accumulation (in air-cooled chillers), or scaling (in water-cooled chillers), it’s recommended to clean them every six months to ensure optimal heat transfer.

Routine Inspection of the Compressor

The compressor’s quality directly affects the stability of the entire refrigeration system. Due to its high precision and relatively high cost, both procurement and maintenance are expensive. Therefore, daily inspection is essential. If abnormal noises or issues with the lubrication system are detected, immediate repairs should be carried out.

Periodic Check of the Expansion Valve

Both the condenser and evaporator are pressure vessels. For safety reasons, the expansion valve must remain in good condition to ensure proper pressure relief and avoid risks of injury to operators.

Monitoring the Refrigerant Level

Industrial refrigerant is the key medium for enabling cyclic cooling. Special attention should be paid to refrigerant levels and the presence of excess moisture in the system. Low refrigerant levels will significantly reduce cooling efficiency, while excessive moisture can impair the refrigerant cycle and lead to cooling failures. Always be prepared to top up refrigerant as needed, and consider installing a filter dryer to remove moisture if required.

Inspection of the Quick Drain Valve

Regular draining helps prevent corrosion and prolongs the service life of your chiller. Installing a quick drain valve is recommended. Open and close the valve three times a week to flush the system and prevent pipe corrosion.

Regular Replacement of Lubricating Oil

As the chiller operates, the lubricating oil gradually absorbs impurities and moisture, degrading its quality and lubrication performance. Regularly check oil levels and oil quality. If anomalies are detected, replenish or replace the lubricant promptly. Ensure only high-quality lubricants are used during replacement.

Regular Pipe Inspection and Cleaning

Piping is essential for the system’s heat transfer process. Leaks caused by cracks or blockages due to scale and debris will drastically reduce cooling efficiency. At least one pipe cleaning per year is recommended. Use the chiller’s fault alarm system to monitor performance and catch issues early before they escalate.

Conclusion

Once an industrial chiller breaks down, the repair cost is often the least of your concerns — the real losses come from reduced production efficiency and compromised product quality. That’s why it is crucial to prioritize the regular maintenance of chiller.

Refrigeratori consigliati

LT 10℃~30℃

macchina refrigerante

capacità di raffreddamento 3kW~14kW

flusso della pompa di circolazione 30L/min 1,6bar~50L/min 2bar

LT -25℃~30℃

circolatori di raffreddamento

capacità di raffreddamento 1kW~5kW

Portata della pompa di circolazione 30L/min 1,6bar

precisione della temperatura ±0,5

LT -45℃~30℃

refrigeratori di precisione

capacità di raffreddamento 0,7kW~4,8kW

Portata della pompa di circolazione 30L/min 1,6bar

precisione della temperatura ±0,5

LT -60℃~-30℃

circolatori refrigerati

capacità di raffreddamento 0,7kW~4,8kW

Portata della pompa di circolazione 30L/min 1,6bar

precisione della temperatura ±0,5

LT -80℃~-40℃

refrigeratori a ciclo chiuso

capacità di raffreddamento 0,4kW~2,5kW

Portata della pompa di circolazione 30L/min 1,6bar

precisione della temperatura ±0,5

LT-800 -18~30℃

mini refrigeratore

capacità di raffreddamento 0,35kW~0,9kW

Flusso della pompa di circolazione 10L/min 0,6bar

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore