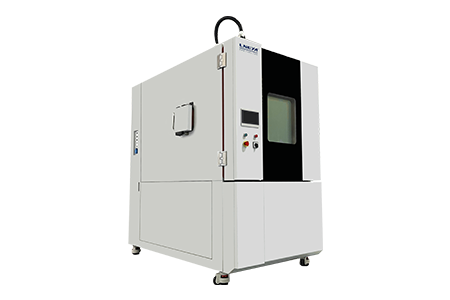

Camera a shock termico

Camere a shock termico di precisione per test a temperature estreme

Il design a due zone consente rapidi cambiamenti di temperatura da -55°C a +180°C con stabilità e controllo superiori.

Camera a shock termico Panoramica

Una camera a shock termico viene utilizzata per testare come materiali e componenti reagiscono a cambiamenti estremi di temperatura. Passando rapidamente tra zone ad alta e bassa temperatura, simula lo stress termico improvviso che i prodotti possono subire negli ambienti reali.

Le camere a shock termico LNEYA sono progettate per un controllo preciso della temperatura, un rapido trasferimento termico e prestazioni affidabili. Ideali per test su elettronica, automotive e aerospaziale, aiutano i produttori a garantire durata, stabilità e affidabilità a lungo termine dei prodotti in condizioni difficili.

Camera a shock termico Caratteristiche

Camera a shock termico Tabella delle specifiche tecniche

| Modalità | GD-200-2-B-CJ | GD-400-2-B-CJ | |

| Dimensioni del cestino (L * A * P) cm | 60*60*60 | 90*65*70 | |

| Intervallo di temperatura d'impatto | |||

| Velocità di riscaldamento della zona di preriscaldamento | (Senza carico) 5 ℃/min (personalizzabile da 10 a 25 ℃) | ||

| Velocità di raffreddamento della zona di pre-raffreddamento | (Senza carico) 2 ℃/min (personalizzabile da 5 a 25 ℃) | ||

| Area di pre-raffreddamento Campo di pre-raffreddamento | -10℃~-55℃ | ||

| Area di preriscaldamento Campo di preriscaldamento | +60~+180℃ | ||

| Tempo di permanenza | ≥30 minuti | ||

| Tempo di recupero | ≤ 5 minuti per recuperare entro ± 2 ℃ | ||

| Fluttuazione della temperatura | ≤1℃ | ||

| Tempo di permanenza | ≥30 minuti | ||

| Tempo di conversione del cestino | ≤10S | ||

| Alimentazione | 380V 50HZ | ||

Ottieni un preventivo dettagliato gratuitamente!

Camera a shock termico Applicazioni

Le camere a shock termico sono ampiamente utilizzate nelle industrie in cui componenti e materiali sono esposti a rapidi cambiamenti di temperatura. Simulando condizioni estreme, una camera di prova a shock termico consente agli ingegneri di valutare la durata e l'affidabilità di componenti elettronici, parti automobilistiche, semiconduttori e altri dispositivi critici.

Durante un test di shock termico, i prodotti subiscono transizioni improvvise tra alte e basse temperature, rivelando potenziali debolezze come crepe, delaminazione o malfunzionamenti. Il test di shock termico in un ambiente controllato aiuta i produttori a identificare e risolvere questi problemi prima della produzione di massa, garantendo una maggiore qualità e sicurezza del prodotto.

I moderni tester per shock termico offrono un controllo preciso sugli intervalli di temperatura e sui tempi di commutazione, rendendo i test di shock termico più efficienti e ripetibili. Che sia per ricerca, controllo qualità o scopi di certificazione, una camera di prova a shock termico è uno strumento essenziale per verificare le prestazioni dei materiali sotto stress termico rapido.

FAQ

CONTATTO

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore